Description

Jiangsu Liangyi professional manufacturer of Inconel 601,UNS N06601,,Alloy 601,Inconel ALloy 601 open die forging parts and seamless rolled steel forged rings from china

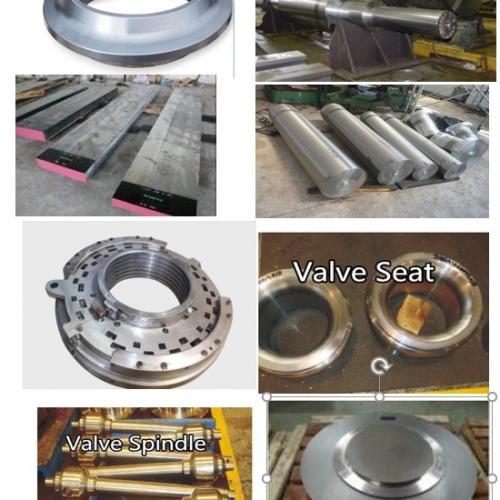

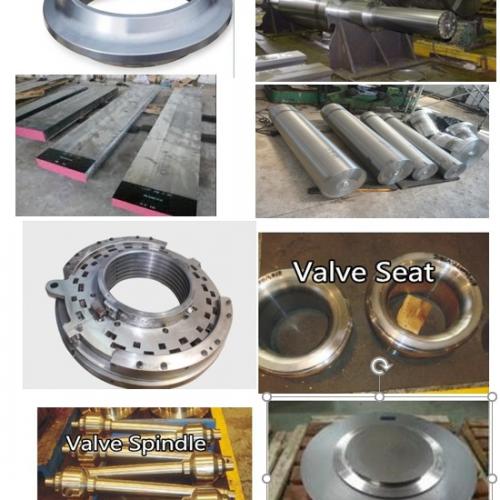

Following is the shape of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601 forging steel material that we could do is:Inconel 601 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 601 Forged forging steel rings seamless rolled rings,Alloy 601 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06601 Forged Forging Steel Discs Disks Blocks plates,Inconel 601 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Inconel 601 is nickel-chromium-iron alloy is a general-purpose engineering material for applications that require resistance to heat and corrosion. The outstanding characteristic of Inconel 601 is its resistance to high-temperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined, and welded.

The composition of alloy 601 is a face-centered-cubic solid solution with a high degree of metallurgical stability. The alloy’s nickel base, in conjunction with a substantial chromium content, provides resistance to many corrosive media and high-temperature environments. Oxidation resistance is further enhanced by the aluminum content.

FOllowing is melting methods of inconel 601 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

FOllowing is chemical compostion of Inconel ALloy 601 forged steel rings

Element %

Nickel:58.0-63.0

Chromium:21.0-25.0

Iron:6-10

Aluminium:1.0-1.7

Carbon:0.10 max

Manganese:1.5 max

Silicon:0.50 max

Sulphur:0.015 max

Copper:1.0 max

Following of Inconel 601 forging parts heat treatment nechanical property Delivery condition :

ASTM B166 – Bar (Annealed)

0.2% Proof Stress MPa MIn 205

Tensile Strength MPa MIn 550

Elongation MPa MIn 30

FOllowing is requirement of inconel 601 forged parts raw material requirement

Ingot: Alloy produced by casting and in suitable form for subsequent forming to the final component geometry.

Billet: Converted material in suitable form for forging.

Freckle: Dark area that is caused by segregation of elements and formation of intermetallic clusters

of carbides,carbo-nitrides,Laves phase or Mu phase etc.

Inclusion: Discontinuity due to metallic or non-metallic impurities.

Segregation: local microstructural change (usually lighter or darker appearance from macro-etching)due

to changes in element concentration.

White spot: Local microstructural change(usually lighter appearance from macro-etching)due to a reduction in content of carbides of hardening elements.

RAW MATERIAL INSPECTION of inconel 601 forging material

The inconel 601 forging billet shall be inspected to ensure that material is uniform in structure and chemistry and free from piping,injurious segregation,discontinuities and other foreign materials.Analysis shall be performed by the billet Producer on material representing at least the top and bottom of each ingot.

RAW MATERIAL CHEMICAL COMPOSITION of inconel 601 forging parts

The composition shall conform to the requirements of Section 6.Copy of the analytical results shall be reported in the forging Supplier's certificate of tests.

The heat analysis shall be determined from samples removed from three forgings of each ingot.The three forgings are the forging at top end,at the bottom end and,for ingots having more than two forgings,the one near the mid-length of the ingot.

ULTRASONIC INSPECTION of inconel 601 forging material

All bilets shall be ultrasonically inspected in accordance with AMS-STD-2154 Type I (immersion method)and acceptance Class AA.All indications above the threshold alarm limit and within the acceptance standard shall be recorded on a map of the billet detaling the observed reading level. Indications above the required acceptance standard shall be removed,by cuting,from the billet.

The section shall then be examined by macrographic and,if necessary,by micrographic examination to assess the nature of the indication.In case of indications due to Freckles,the VAR ingot shall be rejected unless the Freckles is demonstrated to be caused by an isolated melting anomaly.In this case the remaining conform material may be submitted under NCR for EthosEnergy evaluation.

Certiicate of the ultrasonic results and map for each bilet shall be reported in the Supplier's quality documentation

MACRO EXAMINATION of inconel 601 forged parts

One cross surface shall be cut from the top end on the first billet and from the bottom end of the last billet.Additional sections shall be taken from areas containing rejectable defects detected by means of the Ultrasonic Inspection.

Each section shall be identified and polished,macro etched and visually inspected at 1X magnification to ensure absence of voids,inclusions,dirt and dross.The visual inspection shall be performed with reference to an agreed macrographic standard.The macro etching procedure shall

be submitted for approval.

· The billet shall not show circular "Tree Ring Pattern"banding with a severity greater than ASTM A604,Class 4,Severity C.

· Center dendritic pattern shall be less than one third of the billet diameter.

· Dark etching areas shall be further subjected to microscopic examination.Please refer to paragraph 4.3.5 for additional details.

· White spots distribution closer than that shown by ASTM A604,Class 2-Severity B shall be subject to further microscopic examination to confirm their nature and size.

MICRO EXAMINATION of alloy 601 forged parts

Micrographic examination shall be performed on specimens taken in the mid-radius and center of the section used for macrographic examination to evaluate carbide distribution,delta phase distribution,grain and banding.The micrographic samples shall be mounted and polished in the longitudinal direction with respect to the billet.Dedicated additional micrographic inspection shall be performed in case of anomalies are observed at the macrographic inspection.

CARBIDES DISTRIBUTION of alloy 601 forging material

The polished and unetched samples will be examined at 50X to evaluate carbide distribution. Carbides shall be well distributed and shall not form heavy stringers.Obtained results shall be submitted for approval before release the billet.

DELTA PHASE DISTRIBUTION of inconel 601 forged parts

The samples shall be inspected after etching at 400X to evaluate delta phase (Ni3Nb) distribution.No segregation of delta phase shall be present.

GRAIN SIZE DISTRIBUTION of alloy 601 forgings

The average grain size shall be ASTM No.5 or finer.Up to 20%of grain as large as (ALA) ASTM No.2 are allowed.

BANDING of alloy 601 forged parts

The samples shall be inspected,after etching,at 100X to evaluate grain banding.Banding is not acceptable in presence of grain size variation,between fine and large grain bands,larger than #4 ASTM numbers.

Additional micrographic inspection shall be carried UT on dark areas,inclusions,porosity and white spots found during the macrographic/ultrasonic inspections previously performed:

· White spots size shall be recorded on the billet map;

·Dark etching areas classiied as Freckles at the micrographic inspection shall be cause of rejection

Following is forging products of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601 material that is used in following industry

Inconel 601 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy 601 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Inconel 601 forged steel Mechanical Seal Discs

Inconel Alloy 601 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 601 Forged Forging Swept branches outlets steel fittings swept saddles

Inconel Alloy 601 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy 601 Forged Forging venturi cone meter Body Bodies Blocks

UNS N06601 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 601 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Inconel Alloy 601 Forged Forging Steel double studded adapter flange

Inconel Alloy 601 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N06601 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Inconel Alloy 601 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Inconel Alloy 601 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Inconel Alloy 601 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 601 Forged Forging forge Steel transition Cone

UNS N06601 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 601 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Inconel 601 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Inconel 601 Forged Forging Gas steam turbine disks, turbine impeller,turbine rings, turbine bolts, turbine diapharagm nozzles, turbine case

Welcome your inquiry of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601) forging forged steel parts

Following is the shape of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601 forging steel material that we could do is:Inconel 601 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 601 Forged forging steel rings seamless rolled rings,Alloy 601 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06601 Forged Forging Steel Discs Disks Blocks plates,Inconel 601 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Inconel 601 is nickel-chromium-iron alloy is a general-purpose engineering material for applications that require resistance to heat and corrosion. The outstanding characteristic of Inconel 601 is its resistance to high-temperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined, and welded.

The composition of alloy 601 is a face-centered-cubic solid solution with a high degree of metallurgical stability. The alloy’s nickel base, in conjunction with a substantial chromium content, provides resistance to many corrosive media and high-temperature environments. Oxidation resistance is further enhanced by the aluminum content.

FOllowing is melting methods of inconel 601 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

FOllowing is chemical compostion of Inconel ALloy 601 forged steel rings

Element %

Nickel:58.0-63.0

Chromium:21.0-25.0

Iron:6-10

Aluminium:1.0-1.7

Carbon:0.10 max

Manganese:1.5 max

Silicon:0.50 max

Sulphur:0.015 max

Copper:1.0 max

Following of Inconel 601 forging parts heat treatment nechanical property Delivery condition :

ASTM B166 – Bar (Annealed)

0.2% Proof Stress MPa MIn 205

Tensile Strength MPa MIn 550

Elongation MPa MIn 30

FOllowing is requirement of inconel 601 forged parts raw material requirement

Ingot: Alloy produced by casting and in suitable form for subsequent forming to the final component geometry.

Billet: Converted material in suitable form for forging.

Freckle: Dark area that is caused by segregation of elements and formation of intermetallic clusters

of carbides,carbo-nitrides,Laves phase or Mu phase etc.

Inclusion: Discontinuity due to metallic or non-metallic impurities.

Segregation: local microstructural change (usually lighter or darker appearance from macro-etching)due

to changes in element concentration.

White spot: Local microstructural change(usually lighter appearance from macro-etching)due to a reduction in content of carbides of hardening elements.

RAW MATERIAL INSPECTION of inconel 601 forging material

The inconel 601 forging billet shall be inspected to ensure that material is uniform in structure and chemistry and free from piping,injurious segregation,discontinuities and other foreign materials.Analysis shall be performed by the billet Producer on material representing at least the top and bottom of each ingot.

RAW MATERIAL CHEMICAL COMPOSITION of inconel 601 forging parts

The composition shall conform to the requirements of Section 6.Copy of the analytical results shall be reported in the forging Supplier's certificate of tests.

The heat analysis shall be determined from samples removed from three forgings of each ingot.The three forgings are the forging at top end,at the bottom end and,for ingots having more than two forgings,the one near the mid-length of the ingot.

ULTRASONIC INSPECTION of inconel 601 forging material

All bilets shall be ultrasonically inspected in accordance with AMS-STD-2154 Type I (immersion method)and acceptance Class AA.All indications above the threshold alarm limit and within the acceptance standard shall be recorded on a map of the billet detaling the observed reading level. Indications above the required acceptance standard shall be removed,by cuting,from the billet.

The section shall then be examined by macrographic and,if necessary,by micrographic examination to assess the nature of the indication.In case of indications due to Freckles,the VAR ingot shall be rejected unless the Freckles is demonstrated to be caused by an isolated melting anomaly.In this case the remaining conform material may be submitted under NCR for EthosEnergy evaluation.

Certiicate of the ultrasonic results and map for each bilet shall be reported in the Supplier's quality documentation

MACRO EXAMINATION of inconel 601 forged parts

One cross surface shall be cut from the top end on the first billet and from the bottom end of the last billet.Additional sections shall be taken from areas containing rejectable defects detected by means of the Ultrasonic Inspection.

Each section shall be identified and polished,macro etched and visually inspected at 1X magnification to ensure absence of voids,inclusions,dirt and dross.The visual inspection shall be performed with reference to an agreed macrographic standard.The macro etching procedure shall

be submitted for approval.

· The billet shall not show circular "Tree Ring Pattern"banding with a severity greater than ASTM A604,Class 4,Severity C.

· Center dendritic pattern shall be less than one third of the billet diameter.

· Dark etching areas shall be further subjected to microscopic examination.Please refer to paragraph 4.3.5 for additional details.

· White spots distribution closer than that shown by ASTM A604,Class 2-Severity B shall be subject to further microscopic examination to confirm their nature and size.

MICRO EXAMINATION of alloy 601 forged parts

Micrographic examination shall be performed on specimens taken in the mid-radius and center of the section used for macrographic examination to evaluate carbide distribution,delta phase distribution,grain and banding.The micrographic samples shall be mounted and polished in the longitudinal direction with respect to the billet.Dedicated additional micrographic inspection shall be performed in case of anomalies are observed at the macrographic inspection.

CARBIDES DISTRIBUTION of alloy 601 forging material

The polished and unetched samples will be examined at 50X to evaluate carbide distribution. Carbides shall be well distributed and shall not form heavy stringers.Obtained results shall be submitted for approval before release the billet.

DELTA PHASE DISTRIBUTION of inconel 601 forged parts

The samples shall be inspected after etching at 400X to evaluate delta phase (Ni3Nb) distribution.No segregation of delta phase shall be present.

GRAIN SIZE DISTRIBUTION of alloy 601 forgings

The average grain size shall be ASTM No.5 or finer.Up to 20%of grain as large as (ALA) ASTM No.2 are allowed.

BANDING of alloy 601 forged parts

The samples shall be inspected,after etching,at 100X to evaluate grain banding.Banding is not acceptable in presence of grain size variation,between fine and large grain bands,larger than #4 ASTM numbers.

Additional micrographic inspection shall be carried UT on dark areas,inclusions,porosity and white spots found during the macrographic/ultrasonic inspections previously performed:

· White spots size shall be recorded on the billet map;

·Dark etching areas classiied as Freckles at the micrographic inspection shall be cause of rejection

Following is forging products of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601 material that is used in following industry

Inconel 601 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy 601 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Inconel 601 forged steel Mechanical Seal Discs

Inconel Alloy 601 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 601 Forged Forging Swept branches outlets steel fittings swept saddles

Inconel Alloy 601 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy 601 Forged Forging venturi cone meter Body Bodies Blocks

UNS N06601 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 601 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Inconel Alloy 601 Forged Forging Steel double studded adapter flange

Inconel Alloy 601 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N06601 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Inconel Alloy 601 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Inconel Alloy 601 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Inconel Alloy 601 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 601 Forged Forging forge Steel transition Cone

UNS N06601 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 601 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Inconel 601 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Inconel 601 Forged Forging Gas steam turbine disks, turbine impeller,turbine rings, turbine bolts, turbine diapharagm nozzles, turbine case

Welcome your inquiry of Inconel 601,Inconel ALloy 601, Alloy 601,UNS N06601) forging forged steel parts