Description

Jiangsu Liangyi professional manufacturer of 17-4pH(UNS S17400,AISI 630,SUS 630,17-4 pH,17/4 Ph,Grade 630),ASTM A564/A705 grade 630, 17-4ph in ASTM A564/A705 open die forging parts and seamless rolled steel forged rings in in delivery Precipitation hardening condition of 17-4PH H900,17-4PH H925,17-4PH H1025,17-4PH H1075,17-4PH H1100,17-4PH H1150,17-4PH H1150M,17-4PH H900 H1150D from china

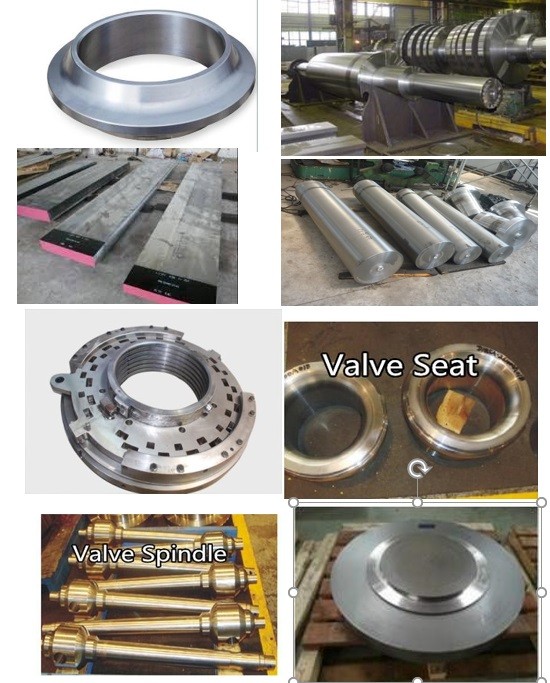

Following is the shape of

17-4pH(UNS S17400,AISI 630,SUS 630,17-4 pH,17/4 Ph,Grade 630)forging steel material that we could do is:17-4pH Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S17400 Forged forging steel rings seamless rolled rings,17-4 pH Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,SUS 630 Forged Forging Steel Discs Disks Blocks plates,AISI 630 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 17-4pH(UNS S17400,AISI 630,SUS 630,17-4 pH,17/4 Ph) material that is used in following industry

17-4pH Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

UNS S17400 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI 630 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Grade 630 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

17-4 pH forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

17-4pH Forged Forging ultra high pressure water jet Waterjet cutting Machine Cutter Hydraulic Cylinder,accumulator attenuator

UNS S17400 forged steel ultra high pressure water jet Waterjet cutting Machine Cutter intensifier pump Sealing Heads

AISI 630 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

SUS 630 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

17/4 Ph forged steel Mechanical Seal Discs

17-4 pH forging steelPost Tensioning Bars

SUS 630 forging steel Gear Timing Adapter Plates

UNS S17400 Forged Forging Marine Ship Boat Propeller Shafts

17-4pH forged steel Pressure Port Sensor housing

UNS S17400 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 630 Forged Forging Gas Air Compressor Rotor

SUS 630 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

17-4 pH Forged Forging Block Adaptor

17-4 pH Forged Forging venturi cone meter Body Bodies Blocks

17/4 Ph Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

Grade 630 Forged Forging Steel gate valves Body Bodies bespoke flat bars

17/4 Ph Forged Forging Steel drill head casings,collars,landing bowls

17/4 Ph forging forged steel Couplings

17-4pH forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

UNS S17400 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 630 Forged Forging Steel Subsea X Tree high pressure elbow

SUS 630 forged forging Steel wellhead locknut Venturi Bench

17-4 pH Forged Forging Steel double studded adapter flange

17/4 Ph Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

17/4 Ph forged steel Downhole drilling tool Mud Motor End Caps

UNS S17400 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

17/4 Ph Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

17-4pH forging Stainless Steel Intake Gate Hoist Cylinder Piston Rods

17-4 pH Forged Forging Steel Pressure Vessel STUDDING OUTLET

AISI 630 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Grade 630 forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

17-4pH Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

17-4pH Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

17-4 pH Forged Forging forge Steel transition Cone

UNS S17400 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

17-4 pH forged forging steel Load Cell

17-4 pH forging steel Homogeniser Homogenising Pumping pistons Plunger

SUS 630 forged Steel Culvert Valve Piston Rods for Miter Gate

17/4 Ph forging steel Hydraulic Cylinder Piston Rod For Miter Gate Machinery

17/4 Ph forged forging steel Tainter Valve Main Rod and Piston Rod

17/4 Ph Forged Forging Duplex Stainless Steel Subsea Manifolds

FOllowing is forging methods of UNS S17400 forged steel rings, :

heateduniformly to 1177 – 1204 °C (2150 – 2200 °F) and held at temperature at least 15 minutes before forging. On sections over 19 mm (0.75 in.)diameter or thickness, the material should be heated for one-half hour perinch of thickness at 1177 – 1204 °C (2150 – 2200 °F) and held forone hour at temperature prior to forging. On reheating, it should be soaked thoroughly. After forging, sections should be cooled to 32 °C

(90 °F) to assure grain refinement. Then, to assure the best condition for the hardening operation, the parts must be reheated to 1024 – 1052 °C(1875 – 1925 °F) and air cooled (or oil quenched or water+polymer

quenched in small 17-4ph forged parts).

Small forgings of 17-4ph forging material may be air cooled. Complex shapes and large forgings of 17-4ph forging parts should be equalized at about 1038 – 1149 °C (1900 – 2100 °F)

before cooling, cooled in air until black, and then slowly cooled to 32 °C (90 °F) under cover of light-gauge nongalvanized sheet or a thin insulating blanket.

FOllowing is chemical compostion of 17-4pH(UNS S17400,AISI 630,SUS 630,17-4 pH,17/4 Ph,Grade 630)forged steel rings

Carbon 0.07% max

Chromium 13.20-14.70%

Manganese 1.00% max

Nickel 5.00-6.00%

Silicon 0.70% max

Molybdenum 1.20-2.00%

Phosphorous 0.035% max

Niobium 0.20-0.70%

Sulphur 0.025% max

Copper 1.20-2.00%

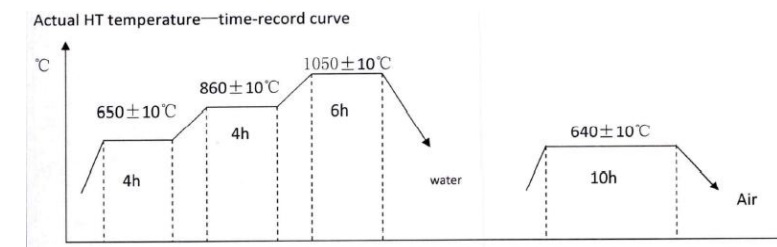

Following of 17-4ph forging parts heat treatment Delivery condition :

Delivery condition Ageing treatment in H900: Tensile strength, Rm: >1310 MPa Yield point, RP0,2: >1170 MPa Elongation, A: >10% Reduction, Z: >40% HB Hardness: >388HRC Hardness: >40

Delivery condition Ageing treatment inH925 Tensile strength, Rm: >1170 MPaYield point, Rp0,2: >1070 MPaElongation, A: >10% Reduction, Z: >44%HB Hardness: >375HRC Hardness: >38 Impact resistance, KV21℃: >6.8 J

Delivery condition Ageing treatment inH1025 Tensile strength, Rm: >1070 MPaYield point, Rp0,2: >1000 MPaElongation, A: >12% Reduction, Z: >45%HB Hardness: >331HRC Hardness: >35 Impact resistance, KV21℃: >20 J

Delivery condition Ageing treatment inH1075 Tensile strength, Rm: >1000 MPaYield point, Rp0,2: >860 MPaElongation, A: >13% Reduction, Z: >45%HB Hardness: >311HRC Hardness: >32 Impact resistance, KV21℃: >27 J

Delivery condition H1100 Tensile strength, Rm: >965 MPaYield point, Rp0,2: >795 MPaElongation, A: >14%. Reduction , Z: >45%HB Hardness: >302HRC Hardness: >31 Impact resistance, KV21℃: >34 J

Delivery condition Ageing treatment in H1150Tensile strength, Rm: >930 MPaYield point, Rp0,2: >725 MPaElongation, A: >16%, Reduction, Z: >50%HB Hardness: >277HRC Hardness: >28I mpact resistance, KV21℃: >41 J

Delivery condition Ageing treatment in H1150MTensile strength, Rm: >795 MPaYield point, Rp0,2: >520 MPaElongation, A: >18%, Reduction , Z: >55%HB Hardness: >255HRC Hardness: >24 Impact resistance, KV21℃: >75 J

Delivery condition Ageing treatment in H1150DTensile strength, Rm: >860 MPaYield point, Rp0,2: >725 MPaElongation, A: >16%, Reduction , Z: >50%HB Hardness: >255HRC Hardness: >24 Impact resistance, KV21℃: >41 J

Following is one 17-4ph forged impeller for our clients

| 3.0 CHEMICAL COMPOSITION of 17-4ph forged impeller | |||||||||||||||

| 3.1. The chemical composition of the forging shall be per ASTM A705, Type 630: | |||||||||||||||

| Carbon 0.07% Max | |||||||||||||||

|

Chromium 15.0% to 17.5% Nickel 3.0% to 5.0% Copper 3.0% to 5.0% Columbium + Tantalum 0.15% to 0.45% Manganese 1.0% Max Phosphorus 0.04% Max Sulphur 0.03% Max Silicon 1.0% Max Iron Remainder |

|||||||||||||||

| 3.2. Chemical analysis is required | |||||||||||||||

| 4.0 FORGING & HEAT TREATMENT: | |||||||||||||||

| 4.1. Charging temperature for billet stock is as follows: | |||||||||||||||

| Billet Thickness - Inches | Max Charge Temp. | ||||||||||||||

| Under 3 | Forging Temperature | ||||||||||||||

| 3 - 6 | 2000。F | ||||||||||||||

| 6 - 8 | 1800。F | ||||||||||||||

| 8 - 10 | 1600。F | ||||||||||||||

| 10 - 12 | 1400。F | ||||||||||||||

| Over 12 | 1200。F | ||||||||||||||

|

4.2. Billet stock should be uniformly raised to forging temperature with no delay in time during the 1750。F to 1850。F heating cycle. |

|||||||||||||||

|

4.3. Material less than ¾” thick is to be forged at 2150OF - 2200OF and should be held for 15 minutes at 2150OF - 2200OF before forging. For forgings exceeding ¾” in thickness, the material is to be heated at 2150OF - 2200OF for one hour before forging. The material should not be heated above 2200OF. Forging temperature should not fall below 1850OF. If 1850OF is reached, the material should be reheated in the furnace to 2150OF - 2200OF. Once the forging is completed, the material should be uniformly cooled in still air with particular attention paid to the 1850OF - 1800OF and 300OF to 90OF range. Material is not to be reworked until the forging temperature is below 90OF. |

|||||||||||||||

|

4.4. All 17-4ph forgings are to be solution annealed by equalizing at 1900OF +/- 25OF and holding for ½ hour minimum per inch of thickness, followed by rapid air cooling to insure complete transformation to martensite. |

|||||||||||||||

| 4.5. HEAT TREAT – CONDITION H1150M: | |||||||||||||||

|

4.5.1. Raise temperature uniformly until part is through heated to 1400OF +/- 15OF and hold for 2 hours. Air cool in still air until part is below 90OF. |

|||||||||||||||

|

4.5.2. Raise temperature uniformly until part is through heated to 1150OF +/- 15OF and hold for 4 hours. Air cool in still air until part is below 90OF. |

|||||||||||||||

| 5.0 MECHANICAL PROPERTIES of 17-4ph forging impeller: | |||||||||||||||

| 5.1. Mechanical properties shall be verified prior to shipment of material. | |||||||||||||||

|

5.2. After heat treatment, test specimen shall be prepared according to standard 0.500-in. diameter round test specimen per Figure 8 of ASTM E8, and tension tested in accordance with ASTM E8. |

|||||||||||||||

| 5.3. Tension test shall produce results conforming to the following: | |||||||||||||||

| Tensile Strength | 123,000 Psi Min. | ||||||||||||||

| 0.2% Yield Strength | 80,000 Psi Min. | ||||||||||||||

| Elongation | 18% Min. | ||||||||||||||

| Reduction of Area | 55% Min. | ||||||||||||||

| Hardness | 31 HRC (306 BHN**) Max. | ||||||||||||||

| ** | |||||||||||||||

|

Hardness conversion to Brinell is approximate and to be used for reference only. Forging vendor shall certify the material Rockwell hardness conforms to this specification. |

|||||||||||||||

| 6.0 TEST SPECIMENS of 17-4ph forging turbine impeller: | |||||||||||||||

|

6.1. Test specimens shall be selected from material that has been subjected to all manufacturing processes and heat treatments of the parent metal. |

|||||||||||||||

| 6.2. Test specimens shall be one inch by one inch by six inch long (1” x 1” x 6”). | |||||||||||||||

|

6.3. A minimum of two (2) prolongations per forging for potential subsequent heat treatment and test shall be provided. |

|||||||||||||||

|

6.3.1. Each test specimen shipped with the forging shall be marked per the requirements of Section 8.0. |

|||||||||||||||

|

6.3.2. These test specimens must be securely affixed, by tack welding, to the respective part from which they were removed prior to shipment of forging. Refer to Figures 1A thru 1C for recommended locations for affixing samples for shipment. |

|||||||||||||||

FIGURE 1A: Samples Affixed to Hub Forging - Fabricated Impellers

FIGURE 1B: Samples Affixed to Hub Forging - Milled Impellers

FIGURE 1C: Samples Affixed to Cover Disc Forging

| 7.0 QUALITY of 17-4ph forging parts : | |||||||||||||||

|

7.1. Forgings shall be free of porosity, internal bursts, flakes, laps, seams, cracks, and rolled-in scale. 7.2. Mechanical properties and other requirements which require certification according to IX. shall be |

|||||||||||||||

| confirmed to be in conformance with this specification prior to shipment of material. | |||||||||||||||

|

7.3. Any parameters which are non-conforming to this specification shall be submitted to Roots for disposition of material. |

|||||||||||||||

| 8.0 MARKINGS of 17-4ph forging impeller : | |||||||||||||||

|

8.1. After machining to forging drawing, each piece shall be stamped in a location as recommended on the drawing or within Figures 2A thru 2C, below. In areas where drawing may differ from Figures 2A thru 2C, the drawing shall take precedence over this specification. Parts shall be stamped with the following information: |

|||||||||||||||

|

8.1.1. Roots purchase order number 8.1.2. Roots part number |

|||||||||||||||

|

8.1.3. Roots material specification (SS30) 8.1.4. Vendor Heat or Serial Number 8.1.5. Foundry’s Name or Trademark |

|||||||||||||||

|

8.1.6. Piece number – to provide traceability to test specimens if multiple quantities of a given part number are ordered under a single purchase order. See 8.2.5. |

|||||||||||||||

|

8.2. Every test specimen delivered with each forging shall be stamped with the following information: 8.2.1. Roots purchase order number 8.2.2. Roots part number |

|||||||||||||||

|

8.2.3. Roots material specification (SS30) 8.2.4. Vendor Heat or Serial Number |

|||||||||||||||

|

8.2.5. Piece Number – to provide traceability to each forging if multiple quantities of a given part number are ordered under a single purchase order. See 8.1.6. |

|||||||||||||||

FIGURE 2A: Location of Part Identification on Hub Forging - Fabricated Impellers

FIGURE 2B: Location of Part Identification on Hub Forging - Milled Impellers

FIGURE 2C: Location of Part Identification on Cover Disc Forging

| 9.0 CERTIFICATION of 17-4ph forging impeller : | |||||||||||||||

|

9.1. The forging supplier shall provide material certificates. At a minimum, the material certificates must contain the following information: |

|||||||||||||||

|

9.1.1. Purchase order number 9.1.2. Roots part number |

|||||||||||||||

|

9.1.3. Roots specification number(SS30) 9.1.4. Vendor name |

|||||||||||||||

| 9.1.5. Heat or serial number | |||||||||||||||

| 9.1.6. Chemical composition (Refer to Section 3.0.) | |||||||||||||||

| 9.1.7. Mechanical properties including hardness (Refer to Section 5.0.) | |||||||||||||||

| 10.0 SUPPLEMENTS: | |||||||||||||||

| S1. This 17-4ph forging requires a modified H1150M condition defined as: | |||||||||||||||

|

Solution anneal forging at 1900OF +/- 25OF. Soak 1/2 hour minimum per inch of thickness. Furnace cool at 200OF max per hour to below 400OF followed by a slow cool in furnace to below 90OF. Allow to sit at room temperature for 1 hour minimum per inch of thickness. |

|||||||||||||||

|

Age harden forging at 1400OF +/- 25OF. Soak for 2 hours + 1/2 hour minimum per inch of thickness. Furnace cool at 200OF max per hour to below 400OF followed by a slow cool in furnace to below 90OF. Allow to sit at room temperature for 1 hour minimum per inch of thickness. |

|||||||||||||||

| Perform second age harden at 1200OF +25OF/-0OF. Soak for 4 hours + 1/2 hour minimum per inch of | |||||||||||||||

|

thickness. Furnace cool at 200OF max per hour to below 400OF followed by a slow cool in furnace to below 90OF. Allow to sit at room temperature for 1 hour minimum per inch of thickness. |

|||||||||||||||

|

All mechanical properties under Section V of this specification still apply for acceptability of material EXCEPT: Hardness 27 HRC (276 BHN**) Max. |

|||||||||||||||

|

**Hardness conversion to Brinell is approximate and to be used for reference only. Forging vendor shall certify the material Rockwell hardness conforms to this specification. |

|||||||||||||||

|

S2. Forging requires ultrasonic inspection. S3. Supplements S1 & S2 both apply. S4. No China content. |

|||||||||||||||

| S5. Supplements S1, S2, & S4 all apply. |

Following is inspection certificate of finished 17-4ph forging impeller

Quality Inspection

Certificate acc. to EN10204-3.1

Product Description

17-4ph Forging Impeller

Materal Grade

17-4ph

CLients

GHECO POwer plant

Purchase Order #

OBM-23-11-0108

Melting Method

EF++VOD+ESR

Quantity

2

Heat #

181-0577

Heat Treat Lot #

23040217

Size (in)

1 inch heighthess,1

Inch width,6 inch length

Delivery Condition

Forged,solution age harddening,heat treatment,

machined to bright surface

Forging Identification Number: WXX-SHDH230216-1-1

Material Specification

As per clients technical document SS30

Productionn Lot Number

JJLY26789

|

Chemical Composition

per ASTM A751 |

|

C% |

Mn% |

Si% |

P% |

Fe% |

S% |

Cr% |

Cu% |

Nb%+Ta% |

Ni% |

|

Min |

|

|

|

|

balance |

|

15.0 |

3.0 |

0.15 |

3.0 |

|

|

Max |

0.07 |

1.0 |

1.0 |

0.040 |

0.03 |

17.5 |

5.0 |

0.45 |

5.0 |

||

|

Actual |

0.044 |

0.77 |

0.17 |

0.023 |

balance |

0.002 |

15.6 |

3.04 |

0.22 |

4.73 |

|

Mechanical Properties

per ASTM E8 |

|

(YS) 0.2%Yield Strength (PSI) |

(TS) Tensile Strength (PSI) |

YS / TS Ratio(%)

|

Elongation

(%) |

Reduction of Area (%) |

Hardness (BHN) |

|

|

|

Surface of parts |

|||||||

|

Min |

123000 |

80000 |

|

18 |

55 |

|

306 |

|

|

Max |

|

|

|

|

|

|

|

|

|

Actual |

139490 |

113100 |

|

20 |

63 |

|

290 |

|

|

NDE Test Results

Note: supporting NDE Reports to be provided! |

Method |

Standard |

Indications |

Results |

|

Ultrasonic Examination |

ASTM A388/388M-16a |

No |

Qualified |

|

|

Magnetic Particle Examination |

ASTM A275/275M |

No |

Qualified |

|

|

Visual Inspection |

|

There is no crack,seams,laps,shrinkage |

Qualified |

FOllowing is one technical requirement of 17-4ph forged bars in 105 K Minimum Yield for Sour Service (API 6A)

Chemical composition of 17-4ph forged bars in API 6A 105K shall conform to the following, when determined in accordance with ASME A564.

Mechanical properrty of 17-4ph forged bars in API 6A 105K

|

D. Heat treatment Practices of 17-4ph forged bars in API 6A 105K : Method A: Double age at 1150º F (620º C) |

|||||||||||||

| Process | Medium | Temperature ºF (º C) | Hold period | ||||||||||

| Solution Anneal | Air or Nitrogen |

1875 – 1925 (1026 – 1050) |

1 hour (Min) | ||||||||||

| Air cool or Suitable liquid quench to below 90º F (32 ºC) (see note 1) | |||||||||||||

| First Age | Air or Nitrogen |

1125 – 1175 (604 – 634) |

4 hours (Min) | ||||||||||

| Air cool or Suitable liquid quench to below 90º F (32 ºC) (see note 1) | |||||||||||||

CHARPY V-NOTCH IMPACT REQUIREMENTS of 17-4ph forged bars in API 6A 105K :

Impact tests shall be conducted as per the procedure of ASTM A-370.The test temperature shall be at or below the temperature specified by the chart given below. A minimum of three impact specimensshall be tested to qualify a single heat of material. If the results are not satisfactory, then a retest shall be conducted using three specimens from the same location within the QTC. Each of the retestspecimen shall meet or exceed the applicable."

Standard size impact specimens measuring 10mm x 10mm in cross sectionshall be used, except where there is insufficient material, in which case the next smaller standard size specimen obtainable shall be

used. When sub size specimens are used the following adjustment factors shall be applicable for PSL 1-3

|

|

|

||||||||||||

|

|

|

||||||||||||

|

|

|

||||||||||||

| 10mm x 2.5mm | 0.333 | ||||||||||||

Requirements chart:

|

Temperature Classification |

Test temperature ºF(ºC) |

Minimum Average impact value J (ft-lbf) |

|||||

| L | -50(-46) | 27 (20) | |||||

| P | -20(-29) | 41 (30) | |||||

Acceptance criteria: Minimum individual value of 3 test specimens should be more than 2/3rd of required average value. Out of three specimens the impact value of two specimens wants to be above the minimum average value.

NON-DESTRUCTIVE EXAMINATION (NDE)of 17-4ph forged bars in API 6A 105K :

1. Visual Inspection (VT):

• Materials shall be VT inspected for 100 percent surface coverage.

• All accessible surfaces shall be free from visible laps, cold shuts, cracks, porosity, slag,scale, and other surface imperfections.

• The results of all VT inspections shall be reported in the documentation package.

2. Ultrasonic Testing (UT):

• Ultrasonic Inspection is required for all raw materials after heat treatment for mechanical Properties exclusive of

stress relief treatments or re-tempering to reduce hardness.

• UT examination methods shall be in accordance with ASTM A388/388M.The examination shall be performed

after heat treatment and prior to any machining operations that would produce examination limitations.

UT acceptance criteria shall be as follows:

1. No single indications exceeding reference distance amplitude curve.

2. No multiple indications exceeding 50% of reference distance amplitude curve. Multiple indications are defined as two or more indications

(each exceeding 50 % of the reference distance amplitude curve) within 13 mm (1/2”) of each other in any direction.

Welcome your inquiry of 17-4pH(UNS S17400,AISI 630,SUS 630,17-4 pH,17/4 Ph,Grade 630) forging forged steel parts