Description

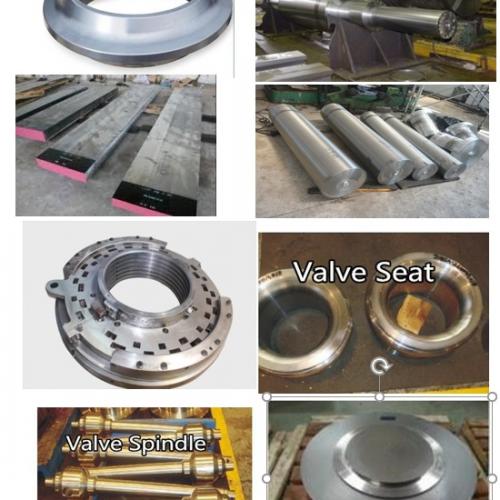

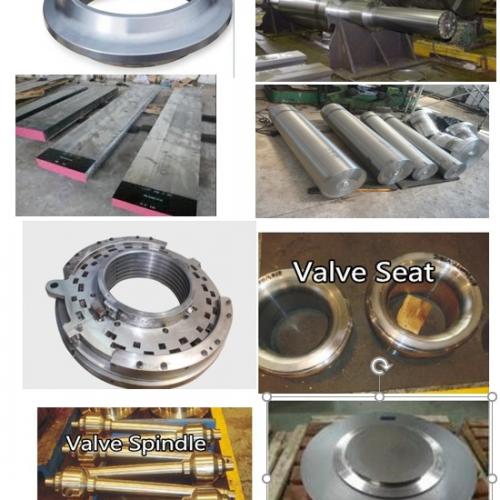

Jiangsu Liangyi is professional manufacturer of AISI 4140,SAE 4140,UNS G41400 open die forging parts and seamless rolled steel forged rings from china

Following is the shape of AISI 4140,SAE 4140,UNS G41400 forging steel material that we could do is:AISI 4140 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 4140 Forged forging steel rings seamless rolled rings,SAE 4140 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 4140 forging forged steel shafts,gear,pinion shafts,spindles,gear wheel,SAE 4140 Forged Forging Steel Discs Disks Blocks plates,AISI 4140 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 4140,SAE 4140,UNS G41400 material that is used in following industry

AISI 4140 Forged Forging Sugar Mill Gear shafts,pinion shafts,roller shafts,flanges coupling

AISI 4140 Cement Mill Rotary Kiln Forged Forging Steel case hardened ground Pinion Shafts

SAE 4140 Forging Forging Steel mill gear pinion shafts

AISI 4140 Forging wind turbine gearbox gear shafts,ring gears

SAE 4140 forging forged locomotive transmission shafts

AISI 4140 forging forged crane wheels

AISI 4140 hydro turbine shafts

AISI 4140 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,

AISI 4140 Forging crankshafts for gas compressor, mechanical presses,pump.

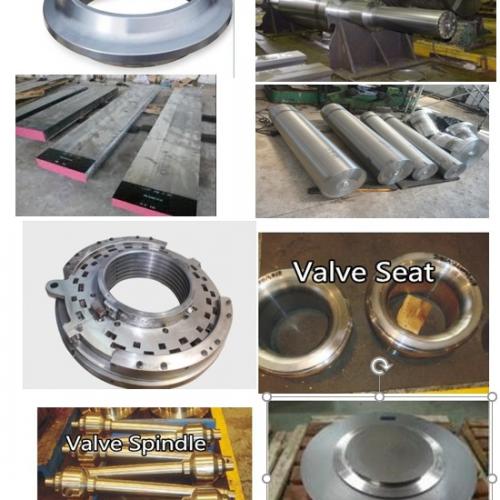

AISI 4140 forging steel Spindles

UNS G41400 Forging steel gear couplings

AISI 4140 Forged Forging Rolled Steel Granulators driers coaters coolers Riding Gear Rings

AISI 4140 Forged Forging Steel Cement Plant Pull Torque Rods

AISI 4140 Forged Forging Steel Crusher Shaft eccentric shafts,Mining Mine rock Gyratory crusher Eccentric shafts Spindles,Crusher Belt Pulley Wheels.

AISI 4140 Forged Forging Steel Mining Excavator Slewing Bearing Ball Races rings

AISI 4140 Forged Forging Steel Oil Drilling Tools Gear Shaft Pinion Shafts

AISI 4140 Forged Forging Steel helical gearing ground ship gearwheel Gear Wheels

AISI 4140 Forged Forging Steel Dragline Drag Line Power Shovel Cam Swing Shafts Shafting Spindles,dragline CENTRE PINTLE

AISI 4140 Forged Forging Steel Atomizer Shafts For Flue Gas Desulfurization scrubber Systems

AISI 4140 Forged Forging Steel drilling rigs Mud pump herringbone gear shafts pinion shafts

AISI 4140 Forging Forged Steel Thread Tie Rods

AISI 4140 Forged Forging Steel Electric Shovel Shaft Couplings

AISI 4140 Forged Forging Steel Granulator Gear Shafts

AISI 4140 Conveyor Pulley Forging Forged Steel Shafts factory

AISI 4140 Forged Forging Steel Hydraulic Honed Cylinders

UNS G41400 Forged Forging Steel Mine hoist systems Equipment Shaft Shafting Spindles

AISI 4140 Forged Forging Steel Rotary Dryer Trunnion Wheels

AISI 4140 Forged Forging Forge Steel Cold Mill Decoiler Coiler Mandrel Drum Shafts

AISI 4140 Forged Forging Steel bullgear Spider Gear Rims

UNS G41400 Forged Forging Shovel SWING Rimmed GEARING Gear DRUM GEAR,SWING PROPEL Pinion SHAFTS

AISI 4140 Forged Forging Steel Truck RING GEARS PLANET GEARS PINION SHAFTS

AISI 4140 Forging Forge Steel Offshore subsea anchor winches Stub Shafts Spindles

UNS G41400 Forged Forging Steel Seamless Hot rolled Truck concrete mixers semi-trailer bearings Rings

AISI 4140 Forged Forging Steel Subsea oil gas drilling equipments Box Riser Joint

AISI 4140 Forged Forging Railway locomotive Traction Motors end housings Rear End Shields

AISI 4140 Forged Forging Steel Gas Steam Turbine Labyrinth seal bushing

AISI 4140 Forged Forging Steel Gas Steam turbine generator air gap annular split baffle rings

AISI 4140 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies

AISI 4140 Forged Forging forge Steel Gas Steam turbine Power generator Shafts

AISI 4140 Forged Forging Gas Steam turbine Rotors Forward Stub Shafts Spindles

AISI 4140 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket factory

AISI 4140 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

AISI 4140 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 4140 Forged Forging Steel double studded adapter flange

AISI 4140 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 4140 Forging/Forged Fracturing Mud Pump Fluid End ModuleForged/Forging Blowout Preventer RAM Annular Bop Body Bodies

AISI 4140 Forged Forging Steel Pumping Equipment Eccentric Laterals Lateral Forgings

SNCM439 Forging Forged Steel shield TBM cutter Cutting Rings

AISI 4140 Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

AISI 4140 Forged Forging Steel drill head casings,collars,landing bowls

AISI 4140 Forged Forging Forge Steel FLANGED BOSSES

AISI 4140 Forged Forging Subsea Extrusions Oil Gas Inventory

AISI 4140 Forged Forging Steel Annulus AWB/PWB wing blocks Body Bodies

AISI 4140 Forged Forging Forge Steel Offshore subsea anchor winches Stub Shafts Spindles

AISI 4140 Forged Forging Steel Lower Torque Hydro Master gate Frac valve Lower Master Valve Block Body Bodies

AISI 4140 Forged Forging Oil field downhole drilling tool Mud Motor Drive shafts

AISI 4140 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AISI 4140 Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies factory

Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies

AISI 4140 is chromium-, molybdenum-, and manganese-containing low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength.

CHEMICAL COMPOSITION of AISI 4140 forged parts

The chemical composition shall be tested on a heat (ladle) basis per ASTM A29 Section 4, or recognized industry standard equivalent, and shall conform to the requirements UNS-G41400 aw. The results of the chemical analysis shall be reported on the certified test report.

Element Content (%)

Chromium, Cr 0.80 – 1.10

Manganese, Mn 0.75 – 1.0

Carbon, C 0.380 – 0.430

Silicon, Si 0.15 – 0.30

Molybdenum, Mo 0.15 – 0.25

Sulfur, S 0.040

Phosphorous, P 0.035

Iron, Fe Balance

The clients may allow the material to be qualified by the use of a check (product) analysis performed on either the test coupon or a non-critical area of the production material. This test shall be performed in accordance with the appropriate ASTM specification as referenced below or recognized equivalent and shall conform to the chemistry listed above with the permissible variance allowed in the referenced ASTM specification

Residual/Trace Elements: Nickel, copper and vanadium are allowed as residual/trace elements (as defined by ASTM A751) within the following tolerances: 0.25% Ni max. for bars, tubulars and forgings; 0.40% Ni max. for plate; 0.35% Cu max. and 0.05% V max. for all mill shape products. Other residual/trace elements are acceptable within concentrations that do not significantly or deleteriously affect the metallurgical or mechanical properties of the alloy. Residual/trace elements need not be reported but must conform to the above requirements.

SUPPLEMENTAL CHEMISTRY REQUIREMENTS of SAE 4140 forged rings: The following supplemental chemistry requirements apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

Phosphorus and sulfur shall be restricted to 0.035 % maximum and 0.040 % maximum respectively.

Phosphorus and sulfur shall be restricted to 0.025% maximum each.

Phosphorus and sulfur shall be restricted to 0.015% maximum each.

Phosphorus and sulfur shall be restricted to 0.015% maximum and 0.010% maximum respectively.

MELTING PRACTICES of AISI 4140 forged parts

The steel shall be melted in accordance with one of the supplemental requirements listed in the section below. The melting practice shall be per Section unless specified by other supplemental requirement.

SUPPLEMENTAL MELTING PRACTICE: The following supplemental melting practices apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

The steel shall be melted by basic oxygen (BOF) or basic electric furnaces (EF). Steel melted in acid furnaces shall not be permitted for the manufacturing of this material. Material processed by vacuum induction melting (VIM) or which receives additional processing by vacuum degassing (VD), argon-oxygen decarburization (AOD), vacuum oxygen decarburization (VOD), electroslag remelting (ESR) or vacuum arc remelting (VAR) shall also be acceptable. The steel shall be fully killed and melted to a fine grain practice.

The steel shall be melted by electric furnace (EF) with subsequent vacuum degassing (VD), argon-oxygen ecarburization (AOD), vacuum oxygen decarburization (VOD), or may be melted by vacuum induction melting (VIM). At the producer soption , additional processing by vacuum arc remelting VAR) or electroslag remelting (ESR) may also be used.

Sulfide shape control by calcium or rare earth injection may also be used.

The melt practice shall be reported on the Certified Test Report.

The minimum forging reduction ratio of AISI 4140 forged bars shall be 4:1, where the forging reduction ratio is defined as the product the area reduction ratio(s) for each hot working operation performed

HEAT TREATMENT of AISI 4140 forged shafts

The production 4140 forged material and test bars shall be supplied in the austenitized, quenched and tempered condition as follows (unless the material is ordered in just the annealed or normalized condition):

A. Austenitize 1550 - 1650 °F (843 - 899 °C

B. Quench

C. Temper:

For hardness less than or equal to 237 HB W 1200 - 1330 °F (649 - 721 °C)

For hardness greater than 237 HBW 800 - 1330 °F (427 - 721 °C)

Note 1: While not mandatory, normalizing may be used to process forgings in an effort to achieve more uniform mechanical properties or response to heat treatment. Normalize (optional) at 1575 - 1675 °F (857 - 913 °C).

Quenching Medium: The preferred quenching medium is oil or water based polymer. Water spray quenching of materials processed on a continuous heat treatment line is considered a direct equivalent to oil quenching or polymer quenching. An alternate quenching medium may be used with written approval of clients

For SAE 4140 forged parts Material Heat Treated in a Batch Furnace:

The minimum time at temperature for the normalizing or austenitizing step of any cycle shall be 30 minutes per inch (12 minutes per cm) of maximum section thickness or one hour, whichever is greater. The minimum time at temperature for the tempering step of any cycle shall be 60 minutes per inch (24 minutes per cm) of maximum section thickness or one hour, whichever is the greater. Realizing that achieving the desired properties in the finished part is the primary objective, ifthe vendor s cycle duration does not conform to the above requirements clients may accept material with a minimum of 20 minutes per inch (8 minutes per cm) or one hour time at temperature, whichever is greater for any step of any cycle. Request for acceptance and/or approval of the use of this provisional criterion shall be in writing.

Approval shall be granted by the cognizant clients. As an alternative, the cycle may be controlled by a heat sink as described in this specification.

The heat treat vendor shall follow a written procedure that includes cycle time(s) and tolerances. The actual cycle time(s) used shall be in accordance with the heat treater's written procedure to ensure the required mechanical properties are obtained. For the purpose of compliance with clients technical manual and we must specify a minimum time at temperature, and that minimum time is 1 minute for normalizing and austenitizing, and 30 minutes for tempering (time in the final soak zone of the furnace). However, clients expects the vendor to use appropriate times based on section thickness, the desired properties and the vendor's own continuous heat treatment process. The temperature for normalizing and austenitizing shall be monitored using an optical pyrometer connected to a recording device. The time at temperature shall be determined according to the heat treat vendor's written procedure.

Quench Media Temperature Requirements: The temperature of the water or quench media used to approximate the cooling rate of water shall not exceed 100 °F (40 °C) at the start of the quench. For bath type quenching the temperature of the water or quench media used to approximate the cooling rate of water shall not exceed 120 °F (50 °C) at the completion of the quench. The temperature range of the other media shall meet the manufacturer swritten

specification.

Heat Treatment Lot of AISI 4140 forged shafts: For batch furnaces, a heat treatment lot shall be defined as material placed on loading or carry devices and moved as a batch through one heat treat cycle in the same furnace. For continuous furnaces, a heat treatment lot shall be defined as a group of pieces of material with the same nominal size that is moved sequentially through the heat treatment process using the same process parameters.

Heat Treatment Documentation of AISI 4140 forged rings: Details of the heat treatment cycle including cycle times, furnace set points and / or part thermocouple temperature, type of quenchant used, and any other pertinent information, shall be reported.

Re-heat Treatment: No more than one re-heat treatment is allowed without the permission of VG. Permission for re-heat treatment shall be requested in writing by the vendor and granted in writing.

SUPPLEMENTAL HEAT TREATMENT REQUIREMENTS of SAE 4140 forged parts: The following supplemental heat treatment practices apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

Furnace Charts: Furnace charts of all heat treatment cycles (or legible copies thereof) shall be provided with the documentation and certification.

Heat Treatment Lot Numbers: The vendor shall assign heat treatment lot numbers to all production material. The heat treatment lot number shall be traceable to specific heat treatment runs and conditions through the vendor s internal documentation. All heat treatment lot numbers shall be recorded on the certified test report.

QUALIFICATION TEST COUPON (QTC) of AISI 4140 forged gear shafts

The mechanical properties required for material produced to this specification shall be determined by testing specimens removed from a QTC. Welding on the QTC shall not be permitted, except for attachment-type-welds.

Material Heat Treated in a Batch Furnace

For material heat treated in batch furnaces, separate test bars, trepanned cores, prolongations or sacrificial production parts may be used as QTC's.

For material heat treated in batch furnaces, the equivalent round of the QTC shall meet or exceed the equivalent round of the part it represents up to a maximum of 5" (127 mm) equivalent round as defined in clients manual and Figure 3. A 4" x 4" x 8" (102 mm x 102 mm x 204 mm) separate test bar meets the requirement for a 5" (127 mm) equivalent round. When the QTC is a trepanned core or a sacrificial production part, the QTC may only qualify production parts having the same or smaller ER. The QTC shall only qualify material and parts produced from the same heat or remelt ingot.

For material heat treated in batch furnaces, multiple QTC's may be used if they are processed through heat treatment using the same furnace set points and times. The test specimens shall be removed from the QTC after all heat treatment has been performed.

AISI 4140 forging Material Heat Treated in a Continuous Furnace

For material heat treated in a continuous furnace, only a sacrificial production part or a prolongation removed from a production part shall be used as the QTC. The sacrificial production part or prolongation QTC shall only qualify production parts having identical size and shape. The QTC shall only qualify material and parts produced from the same heat and heat treatment lot.

For material heat treated in continuous furnaces, multiple QTC's may be used if they are from the same heat and heat treatment lot. The test specimens shall be removed from the QTC after all heat treatment has been performed.

SUPPLEMENTAL QTC REQUIREMENTS of AISI 4140 forged bars : The following supplemental QTC requirements apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

The QTC shall be a sacrificial component or prolongation only.

The mechanical testing shall be performed per heat per heat-treat lot. The testing shall use a prolongation or production part for each heat-treat lot. Individual prolongations or production parts corresponding to each quench shall be used for multiple quench batches from the same furnace load.

TENSILE TESTS of AISI 4140 forged bars

One tensile test shall be performed for each tested QTC between 40°F and 120°F (4°C and 50°C). The test specimen and test method shall be in accordance with ASTM A370 or ISO 6892-1.

Tensile specimens shall be removed from the QTC such that their longitudinal centerline axis is wholly within the center core 1/4 T envelope for a solid QTC or within 1/8 inch (3 mm) of the mid-thickness of the thickest section of a hollow QTC. The tensile specimen gage length shall be at least 1/4 T from the ends of the QTC. When a sacrificial production component is used as the QTC, the tensile specimen shall be removed from a section of the part meeting the size requirements for a QTC for that part as defined in the QTC section. Examples of 1/4 T envelope determination are shown in clients document. For QTC s larger than the specified size the test specimens need not be removed from a location farther from the QTC surface than would be required if the specified QTC size was used.

Standard size ASTM A370 0.5 inch or 12.5 mm gage diameter tensile specimens shall be used. If the physical configuration of the QTC prevents the use of the standard size specimens, then standard sub-size specimens referenced in ASTM A370 may be used.

If the results of the tensile test(s) do not satisfy the applicable requirements, two additional tests (removed from the same location within the same QTC with no additional heat treatment) may be performed in an effort to qualify the material. The results of each of these tests shall satisfy the applicable requirements or all components represented by this QTC shall be rejected, unless further heat treatment is possible (as outlined in this document).

AISI 4140 forged round bars SUPPLEMENTAL TENSILE TEST REQUIREMENTS: The following supplemental tensile test requirements apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

|

CLASS (K) 60 75 80 95 100 110 115 120 |

MIN. YIELD .2% OFFSET PSI (Mpa) 60,000 (414) 75,000 (517) 80,000 (552) 95,000 (655) 100,000 (690) 110,000 (758) 115,000 (793) 120,000 (827) |

MIN. TENSILE PSI (Mpa) 85,000 (586) 95,000 (655) 100,000 (690) 115,000 (793) 120,000 (827) 132,000 (910) 140,000 (965) 145,000 (1000) |

MIN. ELONG. % 18 18 18 17 16 16 15 15 |

MIN. ROA % 35 35 35 35 35 35 30 30 |

||||||||||||||||||||||||||||

IMPACT TESTING of SAE 4140 forged rings

Impact testing shall be performed when required by a specified supplement. Impact tests shall be performed in accordance with the procedures specified in ASTM A370 or ISO 148-1 using the Charpy V-notch technique. When using ISO 148-1, a striker with a radius of 8mm shall be used.

Charpy impact specimens shall be removed from the QTC such that their notch root lies wholly within the center 1/4 T envelope. The Charpy V-notch root shall be at least 1/4 T from the ends of the QTC. When a sacrificial production component is used as the QTC, the impact specimen shall be removed from a section of the part meeting the size requirements for a QTC for that part as defined in the QTC section. Examples of 1/4 T envelopes determination are shown in clients technical document . For QTC s larger than the specified size the test specimens need not be removed from a location farther from the QTC surface than would be required if the specified minimum QTC size was used.

Impact testing shall be performed on a set of three specimens with the test temperature at or below the applicable temperature listed in this specification. Only one set of specimens, all oriented longitudinally or transversely, is required for qualification. Specimens oriented longitudinally with the primary direction of grain flow are preferred

although transverse specimens may be used. Only one orientation need be tested for acceptance. The average energy value for a set of three specimens shall meet or exceed the specified average. No more than one of the specimens shall have an energy value below the specified average and it shall not be below the specified single minimum.

Standard size (as defined by ASTM A370) Charpy V-notch impact specimens 10 mm x 10 mm in cross-section shall be used. If the physical configuration of the QTC prevents the use of standard size specimens, then standard sub-size specimens, in accordance with ASTM A370 shall be used. When sub-size specimens are used the acceptance criteria

(energy values) shall be reduced. The acceptance criterion for sub-size specimens is equal to the acceptance criteria for a standard size specimen multiplied by the adjustment factor specified below.

SPECIMEN SIZE ADJUSTMENT FACTOR

10 mm x 7.5 mm .833

10 mm x 5.0 mm .667

10 mm x 2.5 mm .333

SUPPLEMENTAL AISI 4140 forged parts IMPACT TEST REQUIREMENTS: The following supplemental impact test requirements apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

| LONGITUDINAL | LONGITUDINAL | TRANSVERSE | TRANSVERSE | ||||||||||||||||||||||||||||

| MAXIMUM | AVERAGE | SINGLE | AVERAGE | SINGLE | |||||||||||||||||||||||||||

| TEST TEMP. | ENERGY | MINIMUM | ENERGY | MINIMUM | |||||||||||||||||||||||||||

| °F (°C) | FT-LBS (J) | FT-LBS (J) | FT-LBS (J) | FT-LBS (J) | |||||||||||||||||||||||||||

|

|

0 (-18) | 20 (27) | 14 (19) | 15 (21) | 10 (14) | ||||||||||||||||||||||||||

|

|

0 (-18) | 25 (34) | 20 (27) | 25 (34) | 20 (27) | ||||||||||||||||||||||||||

|

|

0 (-18) | 31 (42) | 25 (34) | 31 (42) | 25 (34) | ||||||||||||||||||||||||||

|

|

0 (-18) | 31 (42) | 21 (28) | 31 (42) | 21 (28) | ||||||||||||||||||||||||||

|

|

-4 (-20) | 31 (42) | 25 (34) | 31 (42) | 25 (34) | ||||||||||||||||||||||||||

|

|

-20 (-29) | 20 (27) | 14 (19) | 15 (21) | 10 (14) | ||||||||||||||||||||||||||

|

|

-20 (-29) | 31 (42) | 25 (34) | 31 (42) | 25 (34) | ||||||||||||||||||||||||||

Unless otherwise specified, each production component shall be hardness tested with one Brinell (10 mm ball, 3000 kgf) hardness test or with one Rockwell C hardness test performed per VGS 8.7.1 on each piece of AISI 4140 forged material. Each AISI 4140 forged component shall have a minimum of one hardness test, although it is recommended that more tests be performed to ensure uniformity. Any conversion to other measurement units shall be made per ASTM E140. Brinell is the preferred method of hardness testing, but clients may elect to use Rockwell C. In the event of a difference between HBW and HRC, Rockwell C will be the acceptance basis for compliance with NACE MR0175/ISO 15156. Hardness values that are below the required values may be evaluated for waiver by clients using the procedure defined in technical manual. Deviations from the hardness limits listed below may be approved by clients if it can be shown that (1) the finished part hardness

requirements can be maintained or (2) the part has adequate strength.

Each QTC shall be hardness tested per ASTM E10 (Brinell), ASTM E18 (Rockwell C), or ASTM E110 at a minimum of one location on the surface after final heat treatment cycle.

SUPPLEMENTAL HARDNESS TESTING REQUIREMENTS: The following supplemental hardness test requirements apply to this specification if referenced by the appropriate supplemental number in the table at the end of this specification.

|

CLASS K 60 75 80 95 100 110 115 120 |

MINIMUM HARDNESS HBW 187 207 217 241 248 269 285 302 |

HBW USING A 20X SCOPE OR AUTOMATED |

|||||||||||||||||||||||||||||

|

9.3.2 9.3.3 9.3.4 9.3.5 9.3.6 9.3.7 9.3.8 |

237 237 237 285 - 302 - 331 341 352 |

||||||||||||||||||||||||||||||

NON-DESTRUCTIVE EXAMINATION (NDE) of finished AISI 4140 forged sleeves

NDE personnel shall be qualified in accordance with requirements specified in ASNT Recommended Practice SNT-TC-1A or ISO 9712.

All NDE instructions shall be approved by an NDE Level III Examiner. For evaluation and interpretation, Level II certification is required as a minimum.

When required, volumetric NDE shall be performed on the material by the vendor unless specifically stated otherwise in the clients part description, in which case the material shall be capable of passing the NDE testing requirements. When testing is required, all examinations shall be performed after all heat treatment for properties exclusive of stress relief treatment or re-tempering to reduce hardness. The vendor shall send NDE test reports with the material test report. In all cases where test capable material is required the vendor need not include a statement of material capability, but must understand that the material will be so tested at clients after receipt. Failure of the material to pass NDE is grounds for rejection of the material.

MARKING of SAE 4140 forged shafts

Each piece of AISI 4140 forged material (including the QTC) shall have the clients part number and the mill heat/heat treat number marked onto its surface (hot stamping, low stress stamping with round v or interrupted dot die is preferred). They shall also have the clients purchase order number durably marked (paint, ink or stamped as above) on their surface. Additional marking may be required by the purchase order.

As an alternative, small products that can be accumulated and palletized, crated or otherwise bundled securely may be segregated by clients part number and mill heat/charge number. The package shall be marked with the clients purchase order number and part number, and mill/charge number. This information shall be attached in such a manner as to be legible upon receipt by clients

Welcome your inquiry of AISI 4140,SAE 4140,UNS G41400 forging parts