Description

Jiangsu Liangyi professional manufacturer of Inconel 600,UNS N06600,,Alloy 600,Inconel ALloy 600 open die forging parts and seamless rolled steel forged rings from china

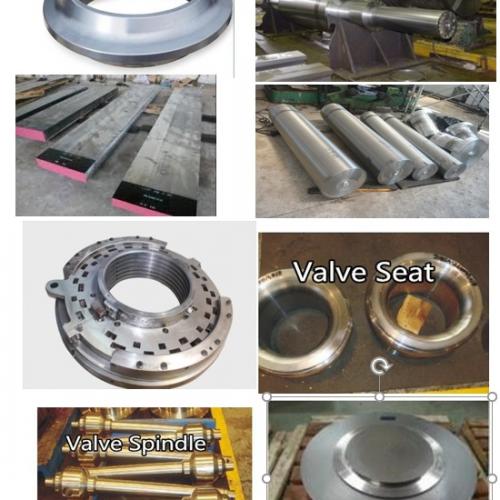

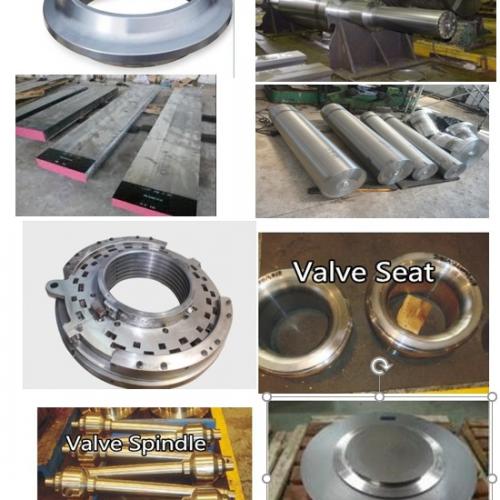

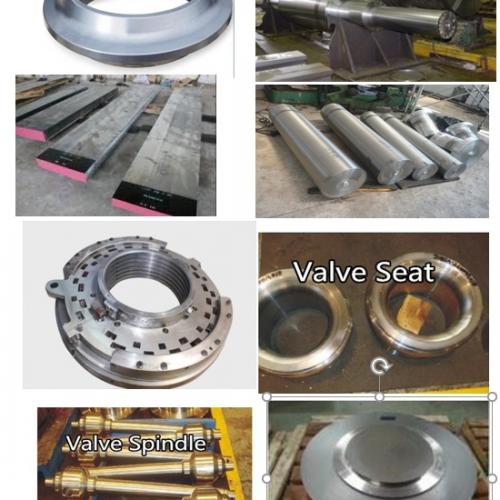

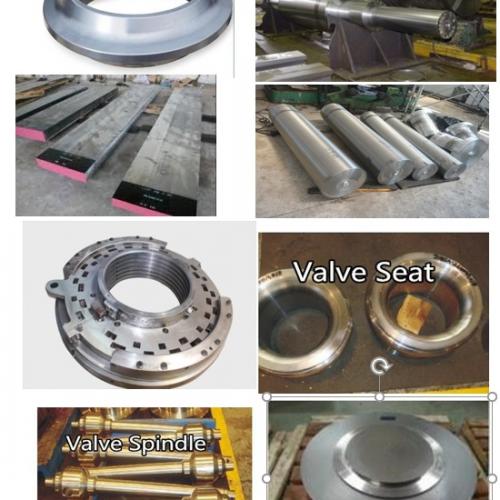

Following is the shape of Inconel 600,Inconel ALloy 600, Alloy 600,UNS N06600 forging steel material that we could do is:Inconel 600 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 600 Forged forging steel rings seamless rolled rings,Alloy 600 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06600 Forged Forging Steel Discs Disks Blocks plates,Inconel 600 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Inconel 600,Inconel ALloy 600, Alloy 600,UNS N06600 material that is used in following industry

Inconel 600 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy 600 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Inconel 600 forged steel Mechanical Seal Discs

Inconel Alloy 600 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 600 Forged Forging Swept branches outlets steel fittings swept saddles

Inconel Alloy 600 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy 600 Forged Forging venturi cone meter Body Bodies Blocks

UNS N06600 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 600 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Inconel Alloy 600 Forged Forging Steel double studded adapter flange

Inconel Alloy 600 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N06600 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Inconel Alloy 600 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Inconel Alloy 600 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Inconel Alloy 600 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 600 Forged Forging forge Steel transition Cone

UNS N06600 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 600 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Inconel 600 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Inconel 600 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

Inconel 600 is a nonmagnetic, nickel-based high temperature alloy possessing an excellent combination of high strength, hot and cold workability, and resistance to ordinary form of corrosion.

Inconel 600 forged material is widely used in Barge and tank truck liners,Carburizing atmospheres,Ethylene dichloride crackers.Furnace trays, mufflers, hangers,Gasoline stabilizer production,MgCl2 evaporates,Phenol condensers,Soap manufacture,Titanium dioxide,Vegetable and fatty acid vessels

FOllowing is melting methods of inconel 600 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

A detailed manufacturing and quality control plan (MQCP)shall be established from us .The plan shall include,for each re-melting method (VIM,ESR,VAR)all the significant operations with frozen parameters. The Supplier shall define internal documentation covering the following as a minimum:

a.Raw material procurement and control (VIM)

b.Type of raw material (Virgin material,revert)and limits on the quantity of each. c.Method used to control the chemical composition.

d.Method used to ensure absence of foreign and non-metallic material.

e.Method for cleaning and inspection of furnaces and electrodes to ensure absence of defects.

f.Method to ensure full traceability of each heat and electrodes.

g.Surface cleaning and conditioning of the ESR ingot for subsequent VAR processing.

h.Method used to ensure absence of foreign and non-metallic material of the produced VAR ingot.

The microstructure of inconel 600 forging parts shall be examined within the areas highlighted on applicable drawings.The microstructure shall also be examined within areas where the macro etch testing has revealed deviations from normal structure that can becaused by coarse grain size.

The microstructure when examined at 100X and 500X magnificationshall be clean and uniform without significant delta phase or primary carbide stringers.Samples shall also be free of laves phase and banding of acicular phase.

The grain size shall be uniform with a grain size of ASTM #7 or finer,determined in accordance with ASTM E112,latest revision.Isolated grains having a maximum size of ASTM #5 are acceptable provided they are randomly distributed and not clustered.

Grain as large as (ALA)ASTM No.2 are permissible provided they are surrounded by fine grains. and the concentration of larger grains is 20%or less of the examined section.

The metallographic sections shall be available to the Purchaser or his representative on request. White spots subjected to micro examinationshall be considered not acceptable if the micrographic evaluation shows one of the following conditions:

·the grain size difference in the white spot is larger than 1.5 ASTM from the part average grain size requirement;

·the white spot area is larger than 8 mm in length;

·the area is associated with voids,dirt,or dross.

Dark etching areas classified as freckles at micrographic inspection and having an ASTM A 604,Class 1-Severity higher than A shall be cause of rejection.

FOllowing is chemical compostion of Inconel ALloy 600 forged steel rings

(Ni+Co) Nickel + Cobalt 72.0 min

(Cr) Chromium 14.0 to 17.0

(Fe) Iron 6.00 to 10.00

(Mn) Manganese 1.00 max

(Si) Silicon 0.50 max

(Cu) Copper 0.50 max

(C) Carbon 0.15 max

(S) Sulfur 0.015 max

Following of Inconel 600 forging parts heat treatment nechanical property Delivery condition :

Yield Strength MPa Min 240

Tensile Strength MPa Min 550

Elongation % min 30

Following is inspection standard of inconel 600 forged pipes

ASTM E8 Tension Testing of Metallic Materials

ASTM E 10 Brinell Hardness of Metallic Materials

ASTM E 18 Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

ASTM E 21 Elevated Temperature Tension Tests of Metallic Materials

ASTM E112 Determining Average Grain Size

ASTM E 139 Conducting Creep,Creep -Rupture,and Stress -Rupture Tests of Metallic Materials

ASTM E 292 Conducting Time -for -Rupture Notch Tension Tests of Materials

ASTM E 354 Chemical Analysis of High-Temp.,Electr.,Magn.,and similar Iron,Nickel,Cobalt Alloys

ASTM A604 Standard practice for macroetch testing of consumable electrode remelted steel bars and billets

ASTM E 930 Estimating the Largest Grain Observed in a Metallographic Section (ALA Grain Size)

ALl our inconel 600 forged shall maintain a complete record of all stages of processing during the manufacture of each forging.Information from these records shall be made available on request for a period of not less than 10 years.

WE shall furnish for each shipment three (3)copies of a dated certified test report,which include the following information:

a.Purchase Agreement Number.

b.PDS Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Total Number of parts per shipment.

e.Heat Number.

f.Raw material source and manufacturing processes and procedures used to produce parts to this specification

g.Heat Treat Temperatures and Holding Times (Heat Treatment Chart)

h.Chemical Composition of each Heat

i.Chemical Composition of each Forging.

j.Tensile Properties of each forging.

k.Results of Creep Rupture Test

l.Hardness of each Forging.

m.Results of Macro Etch Examination (including photographs).

n.Results of Microstructure Examination (including photomicrographs).

o.Results of Nondestructive Examination.

p.Forging Number and Test Number.

q.NCR number,when applicable.

r.Name of Manufacturer.

s.A statement that the forgings conform to all the requirements of this specification,a statement of any deviation applying to the shipment which has received written approval from the Purchaser.A copy of the document approving the deviationshall be attached to the test report.

NOTE:All test results shall be identified with respect to location of test specimens.

Welcome your inquiry of Inconel 600,Inconel ALloy 600, Alloy 600,UNS N06600) forging forged steel parts