Description

Jiangsu Liangyi professional manufacturer of 2.4851,NiCr23Fe open die forging parts and seamless rolled steel forged rings from china

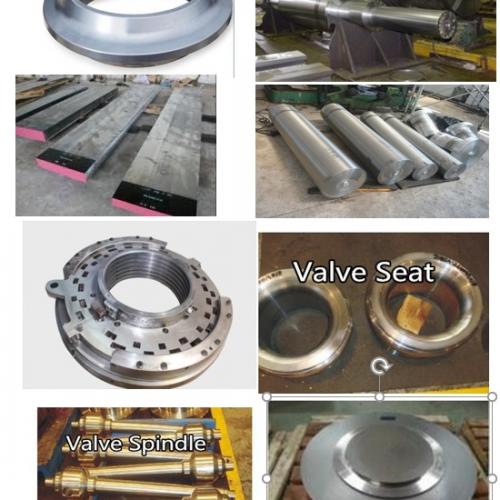

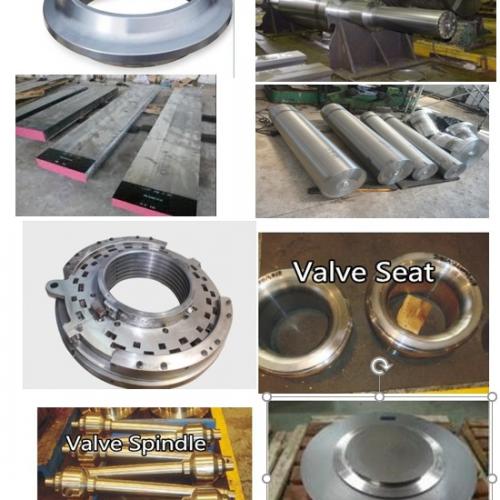

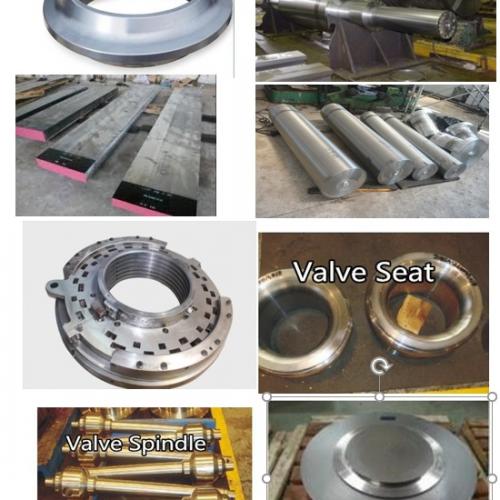

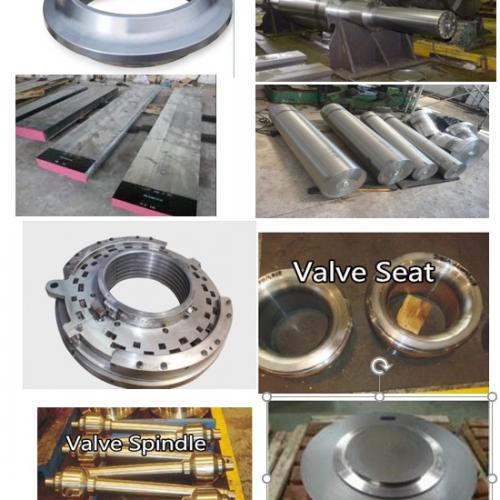

Following is the shape of 2.4851,NiCr23Fe forging steel material that we could do is:2.4851 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4851 Forged forging steel rings seamless rolled rings,NiCr23Fe Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,2.4851 Forged Forging Steel Discs Disks Blocks plates,2.4851 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4851 is is widely used in hermal-processing equipmentbaskets, trays, and fixtures for annealing, carburizing, carbonitriding, nitriding and other heat-treating operations,radiant tubes, muffles, retorts, flame shields, strand-annealing tubes, woven-wire conveyor belts, chain curtains, burner nozzles, and electrical esistance heating elementsthermocouple protection tubes, furnace-atmosphere generators, and infrared radiant screens process heaters, condenser tubes in sour-water strippers, and insulating cans in ammonia reformers combustor components and catalyst grid supports in equipment for nitric acid production. catalyst regenerators and air preheaters in the manufacture of high-density polyethylene. thermal reactors in exhaust systems of gasoline engines and for combustion chambers in solidwaste incinerators superheater tube supports, grid barriers, and ashhandling systems jet-engine igniters and for combustion-can liners, diffuser assembles, and containment rings in gas turbines for aircraft, industrial, and vehicular applications

FOllowing is chemical compostion of 2.4851 forged steel rings

Min% Max%

Ni 58.0 63.0

Cr 21.0 25.0

Fe Bal.

Al 1.0 1.7

C 0.10

Mn 1.0

S 0.015

Si 0.50

Cu 1.0

Following of 2.4851 forging parts heat treatment nechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 550-750

Rp0.2 0.2% proof strength (MPa) (+AT) 205

A - Min. elongation at fracture (%) (+AT) 30

Brinell hardness (HB): (+AT) 220

General:properties of 2.4851 forged parts shall be determined on specimens that have been processed with the production discs and have been heat treated per Section Test material shall not be removed until all heat treatments have been completed

Failure of any test specimen to meet the minimum requirements shall be cause for testing two (2) additional specimens from the same location and in the same orientation as the failed specimen.Failure of either of the two retest specimens shall be cause for rejection.

The tensile and Stress rupture properties of 2.4851 forging material are to be determined in the tangential direction.When not specified on the drawing,they shall be taken on the periphery and midway between the surfaces of the disc forging and midway between inside and outside diameters and on one end of ring forgings.

Tension test specimens shall be per the standard round 13 mm(0.5 inch)diameter 50 mm (2 inch)gage length specimen shown in ASTM A370.When,due to material limitations,the full-size specimen cannot be taken,a reduced diameter specimen may be used but in all cases,the largest possible specimen shall be taken.

NONDESTRUCTIVE EXAMINATION of 2.4851 forging parts

Forging 2.4851 forging material shall be uniform in quality and condition,sound,smooth,clean and free from foreign materials and from internal and external imperfections detrimental to fabrication or performance of the parts.

All forgings 2.4851 parts shall be ultrasonically inspected,after machining to an approved sonic shape,by the Supplier clients technical manual as specified on the relevant drawing or purchase agreement.Disc forgings shall be ultrasonically inspected in the "pancake"configuration prior to contour machining.The Supplier shall make a drawing that describes the UT shape of the disc.The UT shape must be agreed upon between Supplier and Purchaser.

Fluorescent penetrant inspectionshall be carried out on each forging in accordance with clients technical manual as specified on the relevant drawing or purchase agreement.The inspection shall be performed after all machining by the Vendor.

QUAUITY ASSURANCE of our 2.4851 forging parts

1.A detailed Manufacturing and Quality Control Plan (MQCP)including all process stages,listing all manufacturing and inspection points and relevant applicable procedures/work instructions,must be submitted by Supplier for approval.Review,Witness and Holding points shall be highlighted as well and shall be considered subject to review before MQCP approval.

2.The list of "frozen"parameters must be submitted by Supplier at the end of validation process.No further changes will be acceptable unless upon written approval

3.Verification of the manufacturer's quality conformance to the requirements of this specificationshall be made at the place of manufacture or upon receipt of the material by the Purchaser,at the option of the Purchaser.

4.Unless specifically waived by the Quality Assurance Department,all forgings are subject to Source Assurance Inspection and release by inspector prior to shipment.

5.The manufacturer shall notify the Quality Assurance Department of readiness for Source Inspection giving a minimum of ten (10)working days'notice.

6.The manufacturer shall afford the Purchaser's representative,free of cost,all reasonable facilities to satisfy himself that the material is in accordance with this specification.

7.The manufacturers facilties shall be subject to quality assurance auditing by the Purchaser's representative.

8.Material accepted by the Purchaser's representative at the place of manufacture which subsequently reveals imperfections not detected at the place of manufacture or which subsequent tests or analysis show not to be in accordance with this specification,is subject to rejection.

9.Prior to acceptance of new Suppliers or the manufacture of new designs by approved Suppliers,the Purchaser may require that one test forging be destructively tested to determine uniformity of composition, structure and properties.

MARKING of our finished 2.4851 forging parts

Each forging shall be plainly stamped as per clients requirement on one side of the rim,near the periphery, with the following:

a.Purchaser Agreement Number.

b.PDS-Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Forging Number.

e.Test Number.

Forgings shall not be shipped unless stamped by the Purchaser's representative.

Marking methodshall follow the requirements of applicable drawing(s)listed on the Purchase Order.

Following is forging products of 2.4851,NiCr23Fe material that is used in following industry

2.4851 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

NiCr23Fe Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4851 forged steel Mechanical Seal Discs

2.4851 Forged Forging Steel Butterfly Valve Main Shafts Spindles

NiCr23Fe Forged Forging Swept branches outlets steel fittings swept saddles

2.4851 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

NiCr23Fe Forged Forging venturi cone meter Body Bodies Blocks

2.4851 Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4851 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4851 Forged Forging Steel double studded adapter flange

2.4851 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

2.4851 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4851 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4851 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4851 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

NiCr23Fe Forged Forging forge Steel transition Cone

2.4851 Forged Forging Steel Pressure Vessel Reactor Nozzles

NiCr23Fe Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4851 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

2.4851 Forged Forging Gas steam turbine disks, turbine impeller,turbine rings, turbine bolts, turbine diapharagm nozzles, turbine case

Welcome your inquiry of 2.4851,NiCr23Fe forging forged steel parts

Following is the shape of 2.4851,NiCr23Fe forging steel material that we could do is:2.4851 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4851 Forged forging steel rings seamless rolled rings,NiCr23Fe Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,2.4851 Forged Forging Steel Discs Disks Blocks plates,2.4851 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4851 is is widely used in hermal-processing equipmentbaskets, trays, and fixtures for annealing, carburizing, carbonitriding, nitriding and other heat-treating operations,radiant tubes, muffles, retorts, flame shields, strand-annealing tubes, woven-wire conveyor belts, chain curtains, burner nozzles, and electrical esistance heating elementsthermocouple protection tubes, furnace-atmosphere generators, and infrared radiant screens process heaters, condenser tubes in sour-water strippers, and insulating cans in ammonia reformers combustor components and catalyst grid supports in equipment for nitric acid production. catalyst regenerators and air preheaters in the manufacture of high-density polyethylene. thermal reactors in exhaust systems of gasoline engines and for combustion chambers in solidwaste incinerators superheater tube supports, grid barriers, and ashhandling systems jet-engine igniters and for combustion-can liners, diffuser assembles, and containment rings in gas turbines for aircraft, industrial, and vehicular applications

FOllowing is chemical compostion of 2.4851 forged steel rings

Min% Max%

Ni 58.0 63.0

Cr 21.0 25.0

Fe Bal.

Al 1.0 1.7

C 0.10

Mn 1.0

S 0.015

Si 0.50

Cu 1.0

Following of 2.4851 forging parts heat treatment nechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 550-750

Rp0.2 0.2% proof strength (MPa) (+AT) 205

A - Min. elongation at fracture (%) (+AT) 30

Brinell hardness (HB): (+AT) 220

General:properties of 2.4851 forged parts shall be determined on specimens that have been processed with the production discs and have been heat treated per Section Test material shall not be removed until all heat treatments have been completed

Failure of any test specimen to meet the minimum requirements shall be cause for testing two (2) additional specimens from the same location and in the same orientation as the failed specimen.Failure of either of the two retest specimens shall be cause for rejection.

The tensile and Stress rupture properties of 2.4851 forging material are to be determined in the tangential direction.When not specified on the drawing,they shall be taken on the periphery and midway between the surfaces of the disc forging and midway between inside and outside diameters and on one end of ring forgings.

Tension test specimens shall be per the standard round 13 mm(0.5 inch)diameter 50 mm (2 inch)gage length specimen shown in ASTM A370.When,due to material limitations,the full-size specimen cannot be taken,a reduced diameter specimen may be used but in all cases,the largest possible specimen shall be taken.

NONDESTRUCTIVE EXAMINATION of 2.4851 forging parts

Forging 2.4851 forging material shall be uniform in quality and condition,sound,smooth,clean and free from foreign materials and from internal and external imperfections detrimental to fabrication or performance of the parts.

All forgings 2.4851 parts shall be ultrasonically inspected,after machining to an approved sonic shape,by the Supplier clients technical manual as specified on the relevant drawing or purchase agreement.Disc forgings shall be ultrasonically inspected in the "pancake"configuration prior to contour machining.The Supplier shall make a drawing that describes the UT shape of the disc.The UT shape must be agreed upon between Supplier and Purchaser.

Fluorescent penetrant inspectionshall be carried out on each forging in accordance with clients technical manual as specified on the relevant drawing or purchase agreement.The inspection shall be performed after all machining by the Vendor.

QUAUITY ASSURANCE of our 2.4851 forging parts

1.A detailed Manufacturing and Quality Control Plan (MQCP)including all process stages,listing all manufacturing and inspection points and relevant applicable procedures/work instructions,must be submitted by Supplier for approval.Review,Witness and Holding points shall be highlighted as well and shall be considered subject to review before MQCP approval.

2.The list of "frozen"parameters must be submitted by Supplier at the end of validation process.No further changes will be acceptable unless upon written approval

3.Verification of the manufacturer's quality conformance to the requirements of this specificationshall be made at the place of manufacture or upon receipt of the material by the Purchaser,at the option of the Purchaser.

4.Unless specifically waived by the Quality Assurance Department,all forgings are subject to Source Assurance Inspection and release by inspector prior to shipment.

5.The manufacturer shall notify the Quality Assurance Department of readiness for Source Inspection giving a minimum of ten (10)working days'notice.

6.The manufacturer shall afford the Purchaser's representative,free of cost,all reasonable facilities to satisfy himself that the material is in accordance with this specification.

7.The manufacturers facilties shall be subject to quality assurance auditing by the Purchaser's representative.

8.Material accepted by the Purchaser's representative at the place of manufacture which subsequently reveals imperfections not detected at the place of manufacture or which subsequent tests or analysis show not to be in accordance with this specification,is subject to rejection.

9.Prior to acceptance of new Suppliers or the manufacture of new designs by approved Suppliers,the Purchaser may require that one test forging be destructively tested to determine uniformity of composition, structure and properties.

MARKING of our finished 2.4851 forging parts

Each forging shall be plainly stamped as per clients requirement on one side of the rim,near the periphery, with the following:

a.Purchaser Agreement Number.

b.PDS-Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Forging Number.

e.Test Number.

Forgings shall not be shipped unless stamped by the Purchaser's representative.

Marking methodshall follow the requirements of applicable drawing(s)listed on the Purchase Order.

Following is forging products of 2.4851,NiCr23Fe material that is used in following industry

2.4851 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

NiCr23Fe Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4851 forged steel Mechanical Seal Discs

2.4851 Forged Forging Steel Butterfly Valve Main Shafts Spindles

NiCr23Fe Forged Forging Swept branches outlets steel fittings swept saddles

2.4851 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

NiCr23Fe Forged Forging venturi cone meter Body Bodies Blocks

2.4851 Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4851 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4851 Forged Forging Steel double studded adapter flange

2.4851 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

2.4851 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4851 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4851 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4851 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

NiCr23Fe Forged Forging forge Steel transition Cone

2.4851 Forged Forging Steel Pressure Vessel Reactor Nozzles

NiCr23Fe Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4851 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

2.4851 Forged Forging Gas steam turbine disks, turbine impeller,turbine rings, turbine bolts, turbine diapharagm nozzles, turbine case

Welcome your inquiry of 2.4851,NiCr23Fe forging forged steel parts