Description

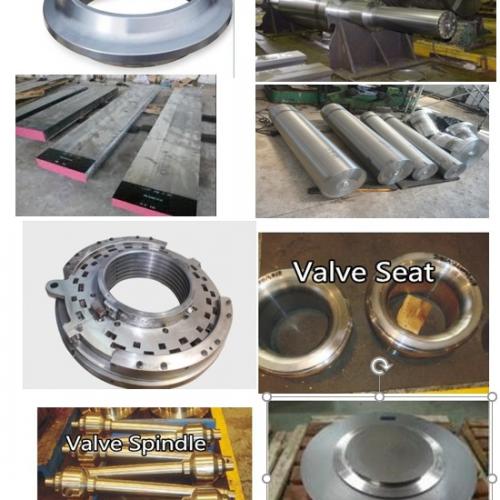

Jiangsu Liangyi is professional manufacturer of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 open die forging parts and seamless rolled steel forged rings from china

Following is the shape of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 forging steel material that we could do is:30NiCrMo16-6 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,30NiCrMo16-6 Forged forging steel rings seamless rolled rings,1.6747 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,30NiCrMo16-6 forging forged steel shafts,gear,pinion shafts,spindles,gear wheel,1.6747 Forged Forging Steel Discs Disks Blocks plates,30NiCrMo16-6 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 material that is used in following industry

30NiCrMo16-6 Forged Forging Sugar Mill Gear shafts,pinion shafts,roller shafts,flanges coupling

30NiCrMo16-6 Cement Mill Rotary Kiln Forged Forging Steel case hardened ground Pinion Shafts

1.6747 Forging Forging Steel mill gear pinion shafts

30NiCrMo16-6 Forging wind turbine gearbox gear shafts,ring gears

1.6747 forging forged locomotive transmission shafts

30NiCrMo16-6 forging forged crane wheels

30NiCrMo16-6 hydro turbine shafts

30NiCrMo16-6 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,

30NiCrMo16-6 Forging crankshafts for gas compressor, mechanical presses,pump.

30NiCrMo16-6 forging steel Spindles

30 NiCrMo 16-6 Forging steel gear couplings

30NiCrMo16-6 Forged Forging Rolled Steel Granulators driers coaters coolers Riding Gear Rings

30NiCrMo16-6 Forged Forging Steel Cement Plant Pull Torque Rods

30NiCrMo16-6 Forged Forging Steel Crusher Shaft eccentric shafts,Mining Mine rock Gyratory crusher Eccentric shafts Spindles,Crusher Belt Pulley Wheels.

30 NiCrMo 16-6 Forged Forging Steel Mining Excavator Slewing Bearing Ball Races rings

30NiCrMo16-6 Forged Forging Steel Oil Drilling Tools Gear Shaft Pinion Shafts

30NiCrMo16-6 Forged Forging Steel helical gearing ground ship gearwheel Gear Wheels

30NiCrMo16-6 Forged Forging Steel Dragline Drag Line Power Shovel Cam Swing Shafts Shafting Spindles,dragline CENTRE PINTLE

30NiCrMo16-6 Forged Forging Steel Atomizer Shafts For Flue Gas Desulfurization scrubber Systems

30NiCrMo16-6 Forged Forging Steel drilling rigs Mud pump herringbone gear shafts pinion shafts

30NiCrMo16-6 Forging Forged Steel Thread Tie Rods

30NiCrMo16-6 Forged Forging Steel Electric Shovel Shaft Couplings

30NiCrMo16-6 Forged Forging Steel Granulator Gear Shafts

30NiCrMo16-6 Conveyor Pulley Forging Forged Steel Shafts factory

30NiCrMo16-6 Forged Forging Steel Hydraulic Honed Cylinders

30 NiCrMo 16-6 Forged Forging Steel Mine hoist systems Equipment Shaft Shafting Spindles

30NiCrMo16-6 Forged Forging Steel Rotary Dryer Trunnion Wheels

30NiCrMo16-6 Forged Forging Forge Steel Cold Mill Decoiler Coiler Mandrel Drum Shafts

30NiCrMo16-6 Forged Forging Steel bullgear Spider Gear Rims

30 NiCrMo 16-6 Forged Forging Shovel SWING Rimmed GEARING Gear DRUM GEAR,SWING PROPEL Pinion SHAFTS

30NiCrMo16-6 Forged Forging Steel Truck RING GEARS PLANET GEARS PINION SHAFTS

30NiCrMo16-6 Forging Forge Steel Offshore subsea anchor winches Stub Shafts Spindles

30 NiCrMo 16-6 Forged Forging Steel Seamless Hot rolled Truck concrete mixers semi-trailer bearings Rings

30NiCrMo16-6 Forged Forging Steel Subsea oil gas drilling equipments Box Riser Joint

30NiCrMo16-6 Forged Forging Railway locomotive Traction Motors end housings Rear End Shields

30NiCrMo16-6 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies

30NiCrMo16-6 Forged Forging forge Steel Gas Steam turbine Power generator Shafts

30NiCrMo16-6 Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies factory

Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies

30NiCrMo16-6 is a high strength quench and tempering steel with high hardenability, excellent toughness, high wear resistance and good dimension stability.

The 430NiCrMo16-6 forged parts shall be melted by one of the following processes:electric furnace with separate degassing and refining optional or electric furnace followed by electroslag-consumable remelting.

Chemical composition of 30 NiCrMo 16-6 forged parts

C 0.26 - 0.33

Si max 0.4

Mn 0.5 - 0.8

Ni 3.3 - 4.3

P max 0.025

S max 0.025

Cr 1.2 - 1.5

Mo 0.3 - 0.6

FOllowing is heat treatment way of 30NiCrMo16-6 forged bars

Hot forging +AR 850-1100°C In air Cooling/quenching

Normalizing +N 900-950°C In air Cooling/quenching

Annealing +A 650-730°C In air Cooling/quenching

Hardening +QT 840-890°C In oil

Tempering +QT 160-700°C In air Cooling/quenching

Mechanical properties of the 30NiCrMo16-6 forged Raw Material

size ≤ 16 yield strength 880 tensile strength 1080-1230 elongation 10 reduction 45

size> 16 ≤ 40 yield strength 880 tensile strength1080-1230 elongation 10 reduction 45

size> 40 ≤ 100 yield strength 880 tensile strength 1080-12300 elongation 10 reduction 45

size> 100≤ 160 yield strength 790 tensile strength 900-1050 elongation 11 reduction 50

size> 160 ≤ 250 yield strength 880 tensile strength 900-10500 elongation 11 reduction 50

Following is production and inspection standard of 30NiCrMo16-6 Forged parts

ISO 643 Steels Micrographic determination of the apparent ferritic or austenic grain size in steels.

ISO 4967 Steels - Determination of the content of non-metallic inclusions -- Micrographic method using standard diagrams.

EN 10083-1 Steels for quenching and tempering Part 1- Special technical delivery conditions.

EN 10083-2 Steels for quenching and tempering Part 2- technical delivery conditions for non alloy steels.

EN 10083-3 Steels for quenching and tempering Part 3- technical delivery conditions for alloy steels.

EN 10250-1 Open die steel forgings for general engineering Part 1- General requirements

EN 10250-2 Open die steel forgings for general engineering Part 2 – Non-alloy quality and special steels

EN 10250-3 Open die steel forgings for general engineering Part 3 – Alloy special steels

EN 10084 Case hardening steels. Technical delivery conditions.

NF A 45-001 General purpose merchant iron and bars Rolling tolerances

EN 10204 Metallic products Types of inspection documents

EN 10308 Non Destructive Testing Ultrasonic inspection of steel bars

EN 10228-3 Non-destructive testing of steel forgings Part 3- Ultrasonic testing of ferritic or martensitic steel forgings.

ALl our 30NiCrMo16-6 forged bars shall issue a certificate of test according to SAE AMS 2154 and EN 10204, cert. 3.1

An inspection certificate 3.1 according EN 10204 of our 30NiCrMo16-6 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Welcome your inquiry of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 forging parts

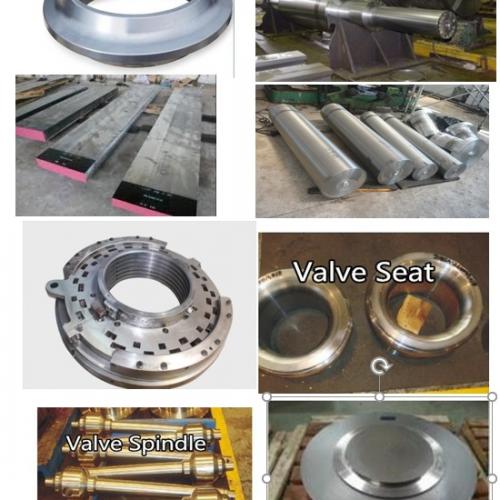

Following is the shape of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 forging steel material that we could do is:30NiCrMo16-6 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,30NiCrMo16-6 Forged forging steel rings seamless rolled rings,1.6747 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,30NiCrMo16-6 forging forged steel shafts,gear,pinion shafts,spindles,gear wheel,1.6747 Forged Forging Steel Discs Disks Blocks plates,30NiCrMo16-6 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 material that is used in following industry

30NiCrMo16-6 Forged Forging Sugar Mill Gear shafts,pinion shafts,roller shafts,flanges coupling

30NiCrMo16-6 Cement Mill Rotary Kiln Forged Forging Steel case hardened ground Pinion Shafts

1.6747 Forging Forging Steel mill gear pinion shafts

30NiCrMo16-6 Forging wind turbine gearbox gear shafts,ring gears

1.6747 forging forged locomotive transmission shafts

30NiCrMo16-6 forging forged crane wheels

30NiCrMo16-6 hydro turbine shafts

30NiCrMo16-6 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,

30NiCrMo16-6 Forging crankshafts for gas compressor, mechanical presses,pump.

30NiCrMo16-6 forging steel Spindles

30 NiCrMo 16-6 Forging steel gear couplings

30NiCrMo16-6 Forged Forging Rolled Steel Granulators driers coaters coolers Riding Gear Rings

30NiCrMo16-6 Forged Forging Steel Cement Plant Pull Torque Rods

30NiCrMo16-6 Forged Forging Steel Crusher Shaft eccentric shafts,Mining Mine rock Gyratory crusher Eccentric shafts Spindles,Crusher Belt Pulley Wheels.

30 NiCrMo 16-6 Forged Forging Steel Mining Excavator Slewing Bearing Ball Races rings

30NiCrMo16-6 Forged Forging Steel Oil Drilling Tools Gear Shaft Pinion Shafts

30NiCrMo16-6 Forged Forging Steel helical gearing ground ship gearwheel Gear Wheels

30NiCrMo16-6 Forged Forging Steel Dragline Drag Line Power Shovel Cam Swing Shafts Shafting Spindles,dragline CENTRE PINTLE

30NiCrMo16-6 Forged Forging Steel Atomizer Shafts For Flue Gas Desulfurization scrubber Systems

30NiCrMo16-6 Forged Forging Steel drilling rigs Mud pump herringbone gear shafts pinion shafts

30NiCrMo16-6 Forging Forged Steel Thread Tie Rods

30NiCrMo16-6 Forged Forging Steel Electric Shovel Shaft Couplings

30NiCrMo16-6 Forged Forging Steel Granulator Gear Shafts

30NiCrMo16-6 Conveyor Pulley Forging Forged Steel Shafts factory

30NiCrMo16-6 Forged Forging Steel Hydraulic Honed Cylinders

30 NiCrMo 16-6 Forged Forging Steel Mine hoist systems Equipment Shaft Shafting Spindles

30NiCrMo16-6 Forged Forging Steel Rotary Dryer Trunnion Wheels

30NiCrMo16-6 Forged Forging Forge Steel Cold Mill Decoiler Coiler Mandrel Drum Shafts

30NiCrMo16-6 Forged Forging Steel bullgear Spider Gear Rims

30 NiCrMo 16-6 Forged Forging Shovel SWING Rimmed GEARING Gear DRUM GEAR,SWING PROPEL Pinion SHAFTS

30NiCrMo16-6 Forged Forging Steel Truck RING GEARS PLANET GEARS PINION SHAFTS

30NiCrMo16-6 Forging Forge Steel Offshore subsea anchor winches Stub Shafts Spindles

30 NiCrMo 16-6 Forged Forging Steel Seamless Hot rolled Truck concrete mixers semi-trailer bearings Rings

30NiCrMo16-6 Forged Forging Steel Subsea oil gas drilling equipments Box Riser Joint

30NiCrMo16-6 Forged Forging Railway locomotive Traction Motors end housings Rear End Shields

30NiCrMo16-6 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies

30NiCrMo16-6 Forged Forging forge Steel Gas Steam turbine Power generator Shafts

30NiCrMo16-6 Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies factory

Forged Forging Steel Rotary Rock Drilling Tri-Cone Tricone Drill Bit cutter (PDC) Body Bodies

30NiCrMo16-6 is a high strength quench and tempering steel with high hardenability, excellent toughness, high wear resistance and good dimension stability.

The 430NiCrMo16-6 forged parts shall be melted by one of the following processes:electric furnace with separate degassing and refining optional or electric furnace followed by electroslag-consumable remelting.

Chemical composition of 30 NiCrMo 16-6 forged parts

C 0.26 - 0.33

Si max 0.4

Mn 0.5 - 0.8

Ni 3.3 - 4.3

P max 0.025

S max 0.025

Cr 1.2 - 1.5

Mo 0.3 - 0.6

FOllowing is heat treatment way of 30NiCrMo16-6 forged bars

Hot forging +AR 850-1100°C In air Cooling/quenching

Normalizing +N 900-950°C In air Cooling/quenching

Annealing +A 650-730°C In air Cooling/quenching

Hardening +QT 840-890°C In oil

Tempering +QT 160-700°C In air Cooling/quenching

Mechanical properties of the 30NiCrMo16-6 forged Raw Material

size ≤ 16 yield strength 880 tensile strength 1080-1230 elongation 10 reduction 45

size> 16 ≤ 40 yield strength 880 tensile strength1080-1230 elongation 10 reduction 45

size> 40 ≤ 100 yield strength 880 tensile strength 1080-12300 elongation 10 reduction 45

size> 100≤ 160 yield strength 790 tensile strength 900-1050 elongation 11 reduction 50

size> 160 ≤ 250 yield strength 880 tensile strength 900-10500 elongation 11 reduction 50

Following is production and inspection standard of 30NiCrMo16-6 Forged parts

ISO 643 Steels Micrographic determination of the apparent ferritic or austenic grain size in steels.

ISO 4967 Steels - Determination of the content of non-metallic inclusions -- Micrographic method using standard diagrams.

EN 10083-1 Steels for quenching and tempering Part 1- Special technical delivery conditions.

EN 10083-2 Steels for quenching and tempering Part 2- technical delivery conditions for non alloy steels.

EN 10083-3 Steels for quenching and tempering Part 3- technical delivery conditions for alloy steels.

EN 10250-1 Open die steel forgings for general engineering Part 1- General requirements

EN 10250-2 Open die steel forgings for general engineering Part 2 – Non-alloy quality and special steels

EN 10250-3 Open die steel forgings for general engineering Part 3 – Alloy special steels

EN 10084 Case hardening steels. Technical delivery conditions.

NF A 45-001 General purpose merchant iron and bars Rolling tolerances

EN 10204 Metallic products Types of inspection documents

EN 10308 Non Destructive Testing Ultrasonic inspection of steel bars

EN 10228-3 Non-destructive testing of steel forgings Part 3- Ultrasonic testing of ferritic or martensitic steel forgings.

ALl our 30NiCrMo16-6 forged bars shall issue a certificate of test according to SAE AMS 2154 and EN 10204, cert. 3.1

An inspection certificate 3.1 according EN 10204 of our 30NiCrMo16-6 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Welcome your inquiry of 30NiCrMo16-6,30 NiCrMo 16-6,1.6747,30NiCrMo16.6,30NiCrMo166 forging parts