Description

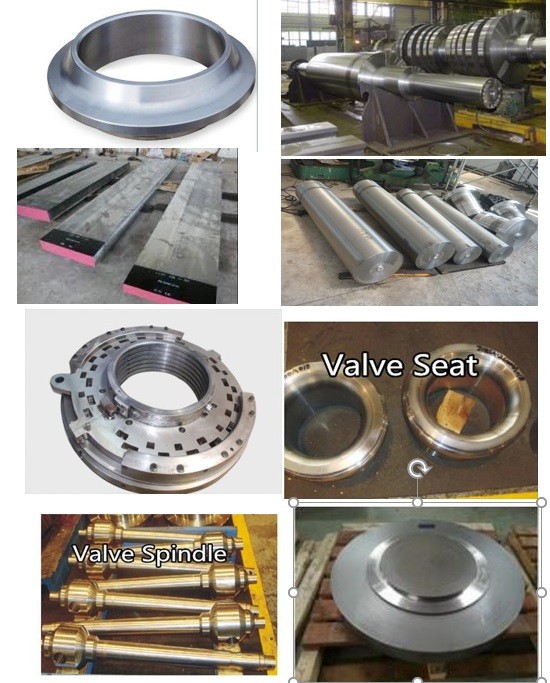

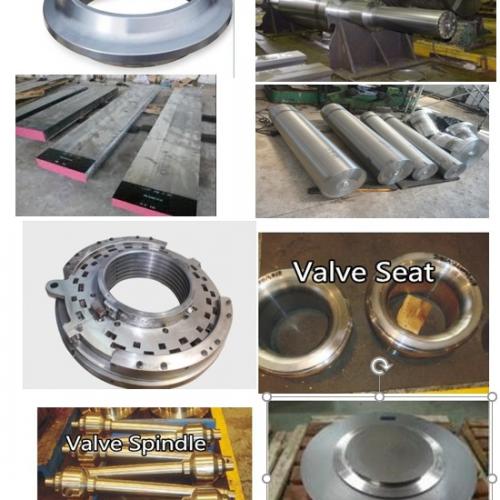

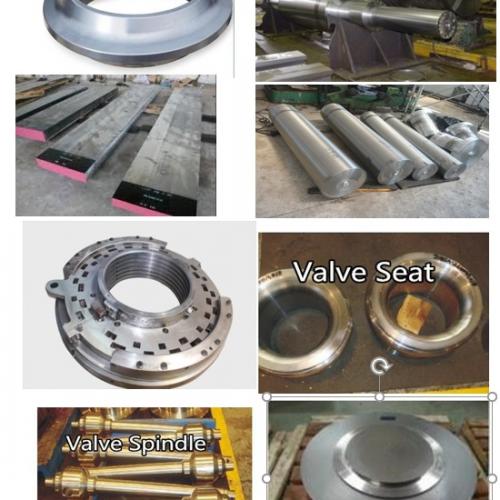

Following is the shape of HASTELLOY Alloy X, HASTELLOY X, ALloy X,UNS N06002 forging steel material that we could do is:HASTELLOY X Forged Steel round bars square bars Flat bars Rectangles Bars Rods,HASTELLOY Alloy X Forged forging steel rings seamless rolled rings,HASTELLOY X Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06002 Forged Forging Steel Discs Disks Blocks plates,ALloy X Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of HASTELLOY Alloy X, HASTELLOY X, ALloy X,UNS N06002 material that is used in following industry

HASTELLOY Alloy X Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars, nozzle vane.

HASTELLOY X Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy X Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N06002 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

ALloy X forging forged Furnace rolls

UNS N06002 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy X Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

HASTELLOY X forged forging hot working dies,tooling, die blocks,mould, mold.

HASTELLOY X Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

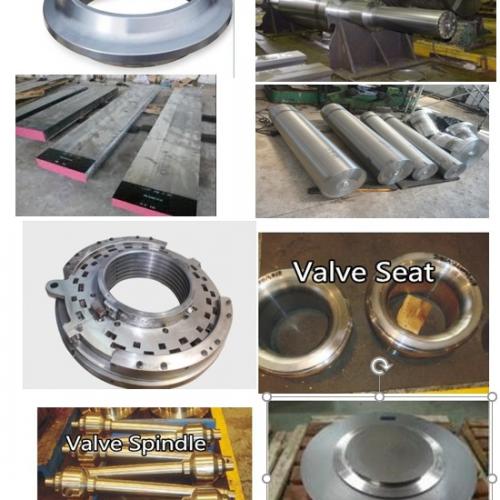

HASTELLOY X Forged Forging Steel power plant steam turbine control reheat valve disc Disk

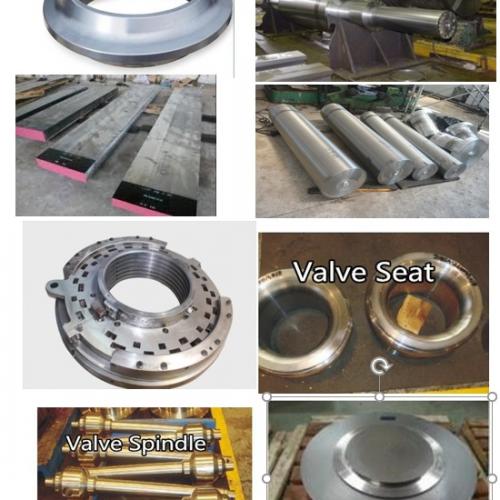

ALloy X Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy X Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

HASTELLOY X forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

Forgings HASTELLOY X maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

Chemical composition of HASTELLOY Alloy X, HASTELLOY X, ALloy X,UNS N06002 forging turbine parts is as

| carbon 0205-0.15 Cobalt | 0.50-2.50 | |||||||||||||

| Manganese 1.00 Max. Molybdenum | 8.00-10.00 | |||||||||||||

| Silicon 1.00 Max. Tungsten | 0.20-1.00 | |||||||||||||

| Phosphorus 0.040 Max. Iron | 17.00~20.00 | |||||||||||||

| Sulfur 0.030 Max. Boron | 0.010 Max. | |||||||||||||

| Chromium 20.50-23.00 Nickel | Remainder | |||||||||||||

HASTELLOY X forging material shall be supplied in one of the following heat treat conditions as specifled on the purchase order of clients

one is Materlal shall be solutlon heat treated by heating to 2150F ,holding at heat for not more than 30 minute, rapid cooling

another one is -material shall be solution heat treated By heating to 1975-2025F holding at heat for not more than 30 minutes and rapidly cooling.Flnal hot rolling and subsequent mill processing temperatures shall not exceed 2025F

|

Nominal Thickness In.Aes |

Tensile Strength psi,min |

Yteld Strength 0.2%Offset psi,min |

EIongation Z in 2 in. or 40,min |

|||||||||||||||

|

ip co 0.010,exc 0.010 to 0.020,excl 0.020 to 0.187,incl Cver 0.187 to 2.000,inc! Uver 2.000 |

105,000 105,000 105,000 100,000 95,000 |

45,000 45,000 45,000 40,900 40,000 |

29 35 35 35 |

|||||||||||||||

|

|

||||||||||||||||||

| A11 thickness | 110.000 | 45、000 | 30 | |||||||||||||||

|

Nominal Thickness inches |

Stress, rs1 |

LiEe hout's |

Elongation %in 2 inches |

|||||||||||||||

|

|

0.010-0.020,exc1, 0.020 and over |

16,000 16,000 |

15 24 |

3 8 |

||||||||||||||

|

|

All | 16,000 | 12 | 8 | ||||||||||||||

Hastelloy X forged Naterial shall withstand,without cracking,bending at room cemperature through the angle indicated below around a dia-meter equal co the bend factor times the nominal thickness of the material,with axis of bend parailel to the direction of rolling.Inspect bend test specinens at 20X magnification.

| normal Thickness Inches |

Angle, degrees,min. |

Bend factor |

|||||||||||||||

|

|

0.010 to 0.050,excl. u.050 to 0.187,incl. |

180 180 |

1.5 2 |

||||||||||||||

|

|

Uo to 0.187,incl | 1S0 | 2 | ||||||||||||||

The hastelloy X forging marerial shall conform to the following grain size requilrements.

| Thickness,inch |

Average grain dlameter ASTM No, or Finer |

|||||||||||||

| Up co 0.125.Lnel | 4 | |||||||||||||

| 0.125 to 0.188,1ncl. | 3 | |||||||||||||

| 0.188 to 2.00,incl. | 2 | |||||||||||||

Mecallographic Inspection of hastelloy alloy X forged bars

total intergranular acrack on forged material shall not extent to a depth greater than .0005 inch

Following is inspection standard of HASTELLOY Alloy X forging material

ASTM E8 Tension Testing of Metallic Materials

ASTM E38 Chemical Analysis of Nickel-Chromium and Nickei-Chromium Iron Alloys

ASTM E112 Estimating the Average Grain Size of Metals

ASTM E139 Coaducting Creep,Creep-Rupture and Stress Rupture Tests oi Metaliic Materials

ASTM A370 mechanical Testing of Steel Products

Following is production standard of HASTELLOY Alloy X, HASTELLOY X, ALloy X,UNS N06002 forging parts

AMS 5754

AMS 5536

ASTM-B572

ASME-B572

Pratt & Whitney LCS F-17

General Electric S-400 / S-SPEC-35

GE B14H74

GE B50A436

GE B50A463

GE B50A249C

Rolls Royce Sabre

Chemical Analyses of hastelloy X forged material shall be conducted in accorcance wich standard ASTM methods.

Chemical check analysis Liimits shall be in accordance with AMS 2269.

For widths 9 inches and over,test specimens shall be taken with the axis rerpendicular to the hastelloy x forging direction.For widths less than 9 inches,test specimens shall be taken with the axil parallel to the forging direction.

Tensile tests of alloy x forged material shall be conducted in accordence with the applicable requirements of ASTM E3.

For reFeree tensile tests,a strain rate of .005 inch/inch/minute through the 0.2%yield strength shall be used.

Stress rupture terts of hastelloy alloy x forged bars shall be conducted in accordance with appiicable requirements of ASTM E139.

Grain size examinatlon of alloy x forged rings shall be performed in accordance with the applicable requlrements of ASTM E112.

Matallographic inspection tests of hastelloy x forged parts shall be cor.ducted at 500X minimum on unetched specimens.

Bend test of alloy x forged plates shall be performed in accordance with the applicable requirement pf ASTM A370.

The hastelloy x forging material manufacturer shall certtfy all chemical and mechanical tests herein speclfied. The manufacturer shall furnish wlth each shipment ment three coples of a certificate of test showing numerical results of tests for chemlcal composition of each heat in the shipment and the numerlcal results of all other required tests and inspections for each thickness of forged parts from each heat. The certificateshalI show that the results are in accordance with the requirements of this specification and shall be mailed by the manufacterer to the purchaser with or preceding the shipment of the material. The certificate shall also contain the following information.

Purchaer order nmber

Heat number

Sizes and quantities

Testing source fcr tensile and stress rupture specimens.

Specific stress rupture stress used

Specification number,CLASS,and revision number

Welcome your inquiry of HASTELLOY Alloy X, HASTELLOY X, ALloy X,UNS N06002 forging parts