Description

Jiangsu Liangyi professional manufacturer of 1.4923/X22CrMoV12-1 open die forging forged parts forged forging rings and forged forging steel gas steam turbine blade vane flat bars factory from china

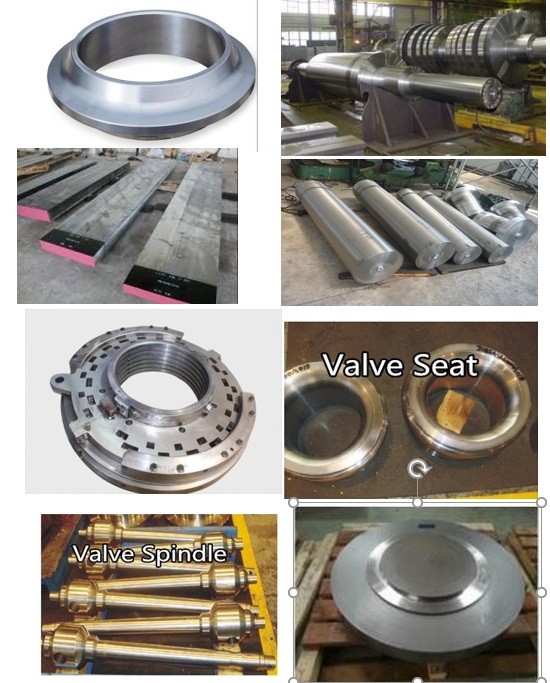

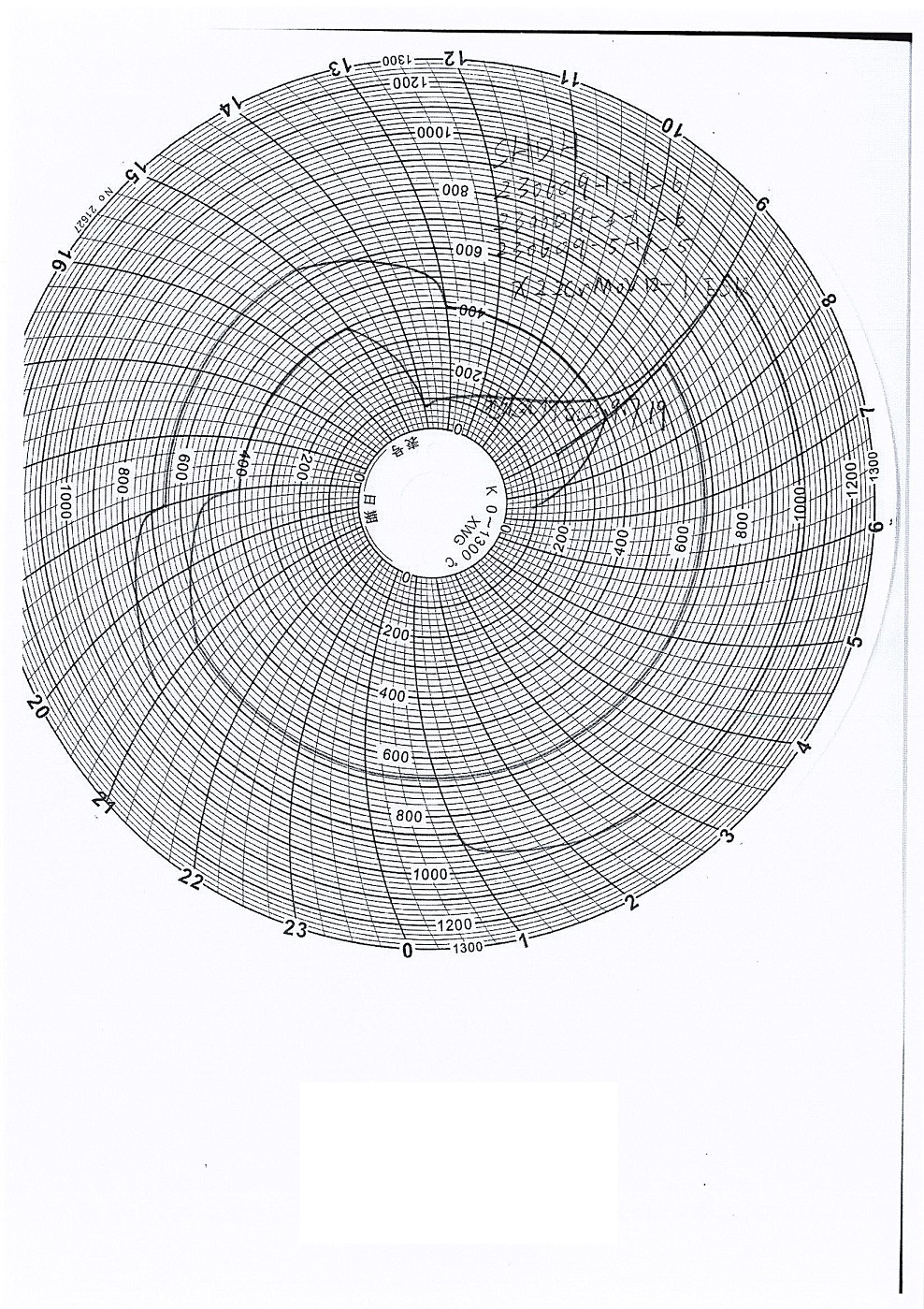

Following is the shape of 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1 forging steel material that we could do is:1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X22CRMOV12-1 Forged forging steel rings seamless rolled rings,1.4923 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X 12 CRMOV 12-1 Forged Forging Steel Discs Disks Blocks plates,X22CrMoV121 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4923 that is used in gas steam turbine

1.4923/X22CrMoV12-1/X22CRMOV121/X22CrMoV12.1 Forged Forging Steel Gas Steam Turbine blade steel

1.4923/X22CrMoV12-1/X22CRMOV121 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

1.4923 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

X22CRMOV121 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

X22CrMoV12-1X22CrMoV12.1 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

X22CrMoV12-1 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

X22CrMoV12-1 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

X22CRMOV121 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

1.4923 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

X 12 CRMOV 12-1 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.4923 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

X22CRMOV121 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

X22CRMOV121 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

X22CrMoV12.1 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

The maximum diamter of 1.4923 forging steel parts in we could produce is 3 meter, the maximum weight of X22CRMOV12-1 forging steel material that we could produce is 25 tons, the maximum length of X22CRMOV12.1 forging steel products that we could do is 12 meter

Following is normal similar grade that we write in 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1

The Melting methods for X22CRMOV12.1 forging steel material is Ef / Eaf + Lf + Vd / ESR that depends on clients needs,The remelted variant (ESR) for 1.4923/X22CrMoV12-1 guarantees the highest purity and homogeneity.

Following is Delivery Condition of 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121 forging steel parts: quenched and tempered (+QT)quench., tempered,stress relieved(+QT+SR),annealed (+A), max. 302 HBW

Following normal production standard for 1.4923,X22CRMOV12-1

AD 2000 Merkblatt W7/W10, EN 10269, DIN EN 10302,VdTUV 110,EN 10204-3.1 , EN 10204-3.2 TUV DNV BV SGS,other production standard in technical manual of 0-2813-4923-00, 105 087 500, 9ANA370206, Alstom, ATM 1230001, BFL 14923, DGTLV-824822001, DGTLV-824831001, Doosan Skoda Power, GTC-1903, HZLM 600134, ITN 02123, ITN 07763, MAN, NB 00141, Q-ST-D-216-000, Siemens TLV 1213, STV M23002, TLV 1105, TLV 1106,

X22CrMoV12-1, 1.4923 is Corrosion-resistant, fire-resistant, chromed steel with a molybdenum additive which is used as a standard for steel components in steam turbines and generators of thermal engines and power plants,aerospace and for pressure and steam boilers.Reactor ,1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121 has an increased creep rupture strength. Scale oxide resistance up to approximately 600°C. The corrosion resistance in natural environment is limited due to the relatively low chromium content. as well as for high temperature connecting components. Thermal resistance up to approximately 600 °C. Corrosion resistance in a natural environment is limited due to the relatively low chrome content. Steam resistant.

1.4923 forging chemnical compostion

Carbon 0.18 to 0.24%

Manganese 0.40 to 0.90%

Silicon ≤ 0.50%

Chromium 11.0 to 12.5%

Vanadium 0.25 to 0.35%

Molybdenum 0.80 to 1.20%

Nickel 0.30 to 0.80%

Phosphorus [Max] 0.025%

Sulphur [Max] 0.015%

Forging temperature of 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1 forging turbine blade vane material is as following

Heat treatment way for 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1 forged material as followings

1.4923 forged parts first hardened by holding the steel at a temperature between 1020 and 1070°C followed by quenching in air, oil or polymer. The tempering temperature is dependent on the desired strength. In most cases a tempering treatment in the temperature range 640 to 740°C followed by air cooling produces the required properties. In this condition, the following mechanical properties can be expected:

Tensile strength Rm = 800 - 950 MPa

Yield point Re > 600 MPa

Elongation A > 14%

Z > 40% Notch toughness

KV > 27 J

Tensile strength Rm = 900 - 1050 MPa

Yield point Re >700 MPa

Elongation A > 11%

Contraction Z > 35%

Notch toughness KV > 20 J

FOllowing is one 1.4923,X22CRMOV12-1 forged blade steel requirement of our one clients

The steel shall be manufactured by basic electric furnace process and subsequently vacuum degassed / electroslag remelted.

The vacuum systemshall have the capacity to maintain a vacuum of 2 torr or lesser during vacuum degassing process for the sufficient time so as to lower the gas contents in the steel.

The ingot castings shall be used for the manufacture of bars. A reduction ratio of 4 (minimum) shall be maintained from the ingot to final bar size. The information regarding the ingot size to the concerned final bar size shall be mentioned in the MIP.

HEAT TREATMENT of 1.4923,X22CRMOV12-1 forged blade steel requirement of our one clients

The following heat treatment is suggested to achieve the mechanical properties specified in clients of this specification.

Harden in air or oil at 1020-1070°C Tempering temperatureshall not be less than 650°C

If the bars need be straightened after heat treatment then the bars shall be stress relieved after the straightening operation at 30° C below the actual tempering temperature with a slow cooling rate.

The process parameters shall be selected with a view to achieve lowest possible residual stresses. The distortion of the finish machined part caused by slight residual stresses from the rolling & heat treatment process shall not occur.

The details of the actual heat treatment cycle followed shall be furnished in the Test Certificate.

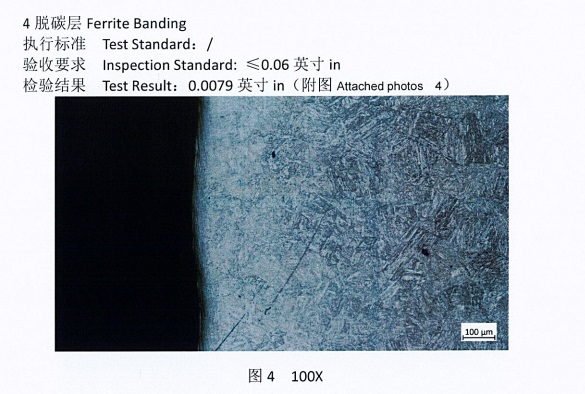

FREEDOM FROM DEFECTS:

The 1.4923,X22CRMOV12-1 forged blade steel bars shall be free from cracks, scabs, seams and other harmful defects.

Decarburization and other material defects shall not exceed the dimensional tolerances

FINISH of 1.4923,X22CRMOV12-1 forged blade steel :

The surface of the bars shall be smooth without any laps, rolled in scales etc. Dents roll marks, and scratches are permitted provided their depth does not exceed half the tolerance limits specified in clause 4.

The edges of bars shall be cut square by sawing or shearing and no crop ends are permissible.

TEST SAMPLES of 1.4923,X22CRMOV12-1 forged blade steel :

For Chemical Analysis: One sample for chemical analysis shall betaken from each melt.

For Mechanical tests: Bars of same size shall be grouped into lots belonging to same melt and heat treatment batch. This shall be treated as a single test unit and subjected to mechanical testing as per following plan.

The uniformity of the strength of the bars belonging to one lot (same melt and heat treatment batch of same size of bars = test unit) shall be verified by hardness test as per EN ISO 6506-1 or any other reputed international method. The hardness test shall be performed on 10% of each test unit, however on atleast 10 bars or on all the bars if the test unit comprises of less than 10 bars. The greatest permissible difference in hardness in a lot (test unit) shall not exceed 35 HBW.

Hardness tests are to be performed after all heat treatments including a possible stress relieving are undertaken.

Mechanical properties shall be determined on the hardest and softest bars identified by the hardness tests conducted

The test samples locations may be as per Annexure A and B. If the cross section of the bar is more than 200 cm2, then mechanical properties must be determined both in the centre of the bar and at the side of the bar. With the exception of toughness, the difference in the properties across the bar cross sectionshall not exceed 7.5%.

The specimen for Metallography shall betaken in longitudinal direction with a minimum cross section area of 320 mm2 .

The positions of the specimens given in the Annexure A and B are meant for guidance only. Details concerning the locations of the specimens are to be agreed mutually and must be included in MIP with a sketch.

CHEMICAL COMPOSITION of 1.4923,X22CRMOV12-1 forged blade steel :

Heat analysis (in weight %) shall be achieved as follows.

|

Element |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

V |

|

Minimum |

0.18 |

0.10 |

0.30 |

-- |

-- |

11.00 |

0.80 |

0.30 |

0.25 |

|

Maximum |

0.24 |

0.50 |

0.80 |

0.020 |

0.020 |

12.50 |

1.20 |

0.80 |

0.35 |

MECHANICAL PROPERTIES of 1.4923,X22CRMOV12-1 forged blade steel :

The material in final delivery conditionshall comply with the following mechanical properties.

|

Properties |

0.2 %Yield Strength, N/mm2 |

Tensile Strength, N/mm2 |

% Elongation |

% Reduction in area |

Impact energy, J |

Hardness (BHN) |

|

Minimum |

700 |

900 |

11 |

35 |

20 |

265 |

|

Maximum |

-- |

1050 |

-- |

-- |

-- |

310 |

NOTE: 1) The tensile test shall be carried out accordance with EN10002 resp. ASTM E8M (round tension test specimen with Lo = 50 mm and do = 10 mm) or any other reputed National/International standard.

The Charpy V – notch impact testshall be performed with standard test specimens in accordance with EN: 10045 or any other reputed National/International standard. An impact testshall consist of three specimens from a single test location; the minimum average value shall be as specified above. Only one value of the three can be below the specified minimum, but in no case below 14 J. All the three test results shall be reported in test certificate.

HBW 10/3000 or HBW 5/750 shall be used for hardness tests.

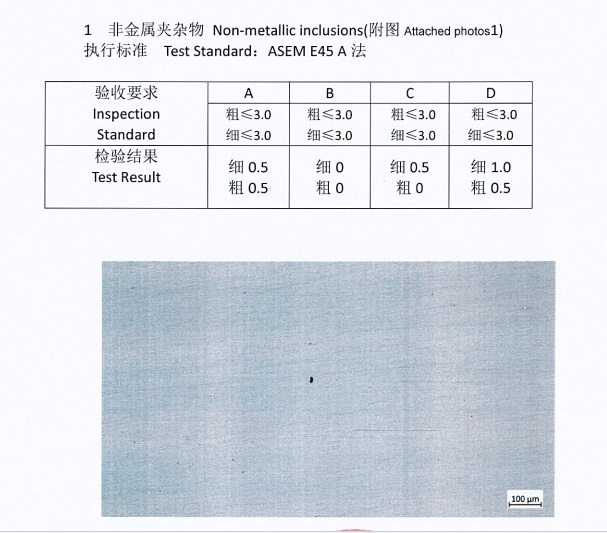

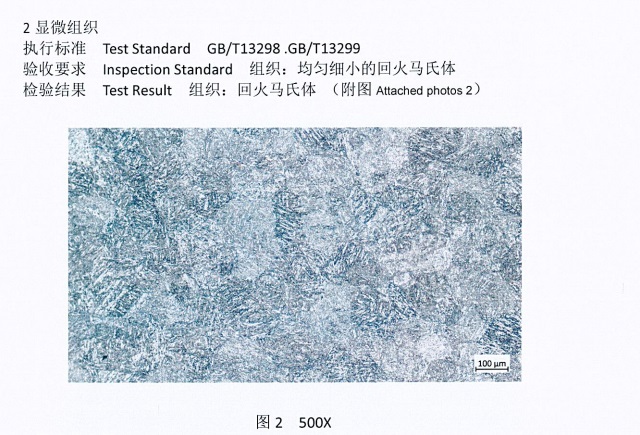

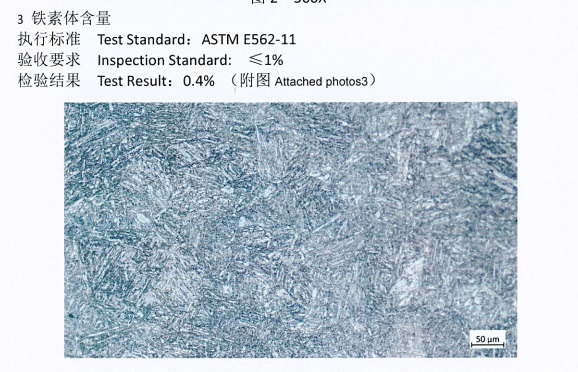

METALLOGRAPHY TESTS of of 1.4923,X22CRMOV12-1 forged blade steel :

The examination of the cleanliness must be performed in the centre of one bar per lot. It can be conducted before or after the heat treatment. The microstructure must be uniform and free from porosity, excessive segregation and other in-homogeneities. The following properties concerning delta- ferrite and inclusions shall be achieved.

Delta ferrite content of 1.4923,X22CRMOV12-1 forged blade steel shall be less than 5%. Delta ferrite content shall be determined in a manner consistent with the evaluation technique described in ASTM E 45 Method A (Worst Field Method at a Magnification of 100X) with the specimen orientation in longitudinal direction. The distribution and size of delta ferrite must be such that it does not result in indication during MPI examination of the ready-machined surface.

Inclusion content shall be tested as per ASTM E 45 Method A and with following limits.

“Thin series” inclusions shall not exceed 2.0 for Type A, B, C and 2.5 for Type D. 13.2.2 “Heavy series” inclusions shall not exceed 1.5 for all Types i.e. A, B, C and D.

All the type and sizes of the inclusions mentioned in 13.2.1 and 13.2.2 can exist simultaneously. 13.2.4 Maximum number and size of globular inclusions (type D):

IR (D) = (n1 + 2.5 n2) ≤ 10

IR (D) is converted to an area of 160 mm2 . n= number of globular inclusions.

n1 (25 μm – 50 μm); n2 (51 μm – 75 μm)

The size pertains not only to the globular inclusions themselves, but also the subsequent cavities, which can occur beside them. Inclusions and cavities which are more than 75 μmare not allowed.

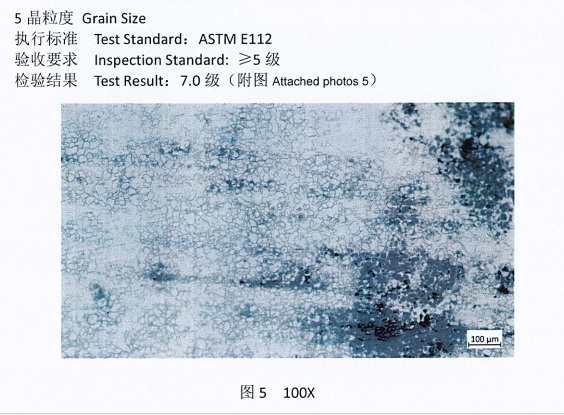

Grain size of of 1.4923,X22CRMOV12-1 forged blade steel : The grain size must be measured at the softest and the hardest bar after all heat treatments are performed. Grain size 4 or finer per ASTM E 112 or DIN 50601 must be achieved. A deviation from the average size of more than 2 grain size is not permissible.

EXTERNAL AND INTERNAL QUALITY/NON DESTRUCTIVE TESTING of 1.4923,X22CRMOV12-1 forged blade steel :

Test Scope: The following NDT inspections shall be performed after all heat treatments including stress relieving operations are completed on the bars

Visual inspection of all 1.4923,X22CRMOV12-1 forged blade steel bars

UT of all 1.4923,X22CRMOV12-1 forged blade steel bars as per to SEP 1923, inspection number D3 or D2 with dual (twin) crystal search unit.

Requirements: 100% of the volume shall be examined with the stipulated recording level.

Criteria for Recording Limits and Decision on Further Use:

Surface defects of 1.4923,X22CRMOV12-1 forged blade steel : Indication of surface defects, e.g., scoring caused by the rolling process are to be ground at least at both ends, in the center of the indications and in increments of ca.250 mm to check the extension below the surface. Surface defects extending ≥1 mm or greater than half the specified dimensional tolerances below the surface are not permissible.

UT: Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification: EE (single echo) and VE (numerous single echoes) without extension ≥ 2 mm CRR are not permissible.

HIGH TEMPERATURE PROPERTIES of 1.4923,X22CRMOV12-1 forged blade steel :

The supplier shall guarantee the elevated temperature properties as per EN10269 for this grade of material.

MATERIAL IDENTITY TEST of 1.4923,X22CRMOV12-1 forged blade steel :

At the time of delivery, all the bars shall be subjected to identification test by Spark test method or any other reliable means to ascertain that the material supplied is as required by the specification.

PROCESS QUALIFICATION of 1.4923,X22CRMOV12-1 forged blade steel :

A qualification review, performed jointly by the purchaser and supplier, is required before starting production for the first order. The process qualification review will include the following as a minimum requirement.

This initial process qualification is required for each manufacturing, heat treatment and testing facility 17.2 The parameters used or stipulated during this phase form the basis of the MIP.

In addition to the scope of testing and examination stipulated in this specification, the following tests and examinations shall be performed.

Tensile and impact tests in transverse direction. If required, the sub-size test specimens may be used for the testing.

Hot tensile test of 1.4923,X22CRMOV12-1 forged blade steel: In accordance with ISO 6892-2 or equivalent standard, a tensile test in longitudinal direction has to be performed at 6000C. The following properties must be achieved:

|

0.2% Proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation (%) |

Reduction in area (%) |

|

≥285 |

≥380 |

≥18 |

≥60 |

Determination of FATT according to ASTM A 370. FATT of < 25°C shall be achieved. Testing shall be carried out on minimum 10 specimens.

Magnetic particle testing of 1.4923,X22CRMOV12-1 forged blade stee : The distribution, type and size of micro-structural in-homogeneities (e.g. delta ferrite and segregation) shall not cause MP indications.

The manufacturers hall provide the sample to clients for evaluation or testing before carrying out creep tests at any suitable labs. Only sample which are evaluated and certified by clients shall be subjected to creep tests.

1 The MIP plan shall include the Creep and hot yield test. The manufacturer shall submit the results of creep tests conducted on the hardened and tempered samples of the steel produced by them of this grade of material. The test parameters like test temperature, duration of test and number of test samples shall be mutually agreed upon between the manufacturer and clients. The results of these creep tests shall form the basis of high temperature property guarantee to be given by the manufacturer for their supplies of1.4923,X22CRMOV12-1 forged blade steel

TEST CERTIFICATE of 1.4923,X22CRMOV12-1 forged blade steel :

Five copies of the test certificate shall be furnished (in English) giving the following details:

a) Specification No.:

b) Clients Order No.

c) Name of the supplier.

d) Melt No.

e) Process of Manufacture

f) Heat treatment batch no. and HT charts.

g) Results of chemical analysis and mechanical tests (including hardness test results).

h) Results of Metallographic tests with representative Photomicrographs.

i) Results of Ultrasonic tests.

j) Dimensional inspection report

k) High temperature guarantee certificate

l) Confirmation of ‘Material identity test’ on all bars

m) Results of any additional test (if applicable as per order)

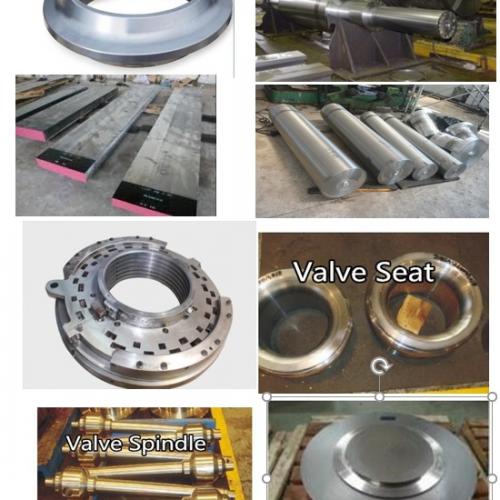

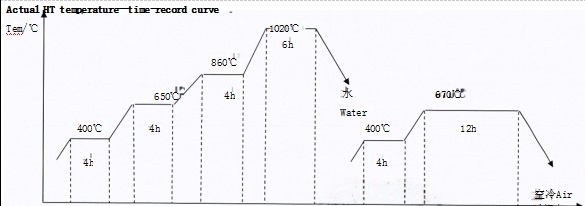

Heat treatment Report X22CrMoV12-1 Forged flat steel flat bars

|

Customer |

Thailand port plant |

Report No |

HT230922001 |

|||||||

|

Model No of thermal treatment Furnace |

Vertical Furnace |

|||||||||

|

HT Process |

Q+T |

Heat treatment No. |

23090719 |

|||||||

|

Drawing No |

Item No |

Job No. |

Material Grade |

Quantity |

Steel ingot No. |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-1 |

X22CrMoV12-1 ESR |

|

1230709 |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-2 |

X22CrMoV12-1 ESR |

|

1230713 |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-3 |

X22CrMoV12-1 ESR |

|

1230714 |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-4 |

X22CrMoV12-1 ESR |

|

1230715 |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-5 |

X22CrMoV12-1 ESR |

|

1230716 |

|||||

|

6.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-1-6 |

X22CrMoV12-1 ESR |

|

1230717 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-1 |

X22CrMoV12-1 ESR |

|

1230701 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-2 |

X22CrMoV12-1 ESR |

|

1230702 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-3 |

X22CrMoV12-1 ESR |

|

1230703 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-4 |

X22CrMoV12-1 ESR |

|

1230704 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-5 |

X22CrMoV12-1 ESR |

1 |

1230705 |

|||||

|

8.25"X8.25"X156" |

Forged square bar |

WXX-SHDH230609-3-6 |

X22CrMoV12-1 ESR |

1 |

1230706 |

|||||

|

8.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-5-1/-2 |

X22CrMoV12-1 ESR |

2 |

1230712 |

|||||

|

8.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-5-3 |

X22CrMoV12-1 ESR |

|

1230707 |

|||||

|

8.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-5-4 |

X22CrMoV12-1 ESR |

|

1230708 |

|||||

|

8.25"X9.5"X156" |

Forged square bar |

WXX-SHDH230609-5-5 |

X22CrMoV12-1 ESR |

1 |

1230710 |

|||||

|

Process Curve For Thermal Treatment |

||||||||||

|

|

||||||||||

|

Actual HT temperature—time-record curve

|

||||||||||

|

Result |

|

|||||||||

|

Inspector |

|

Inspect Date |

2023-09-09 |

人 Verified by |

|

Verify Date |

2023-09-09 |

|||

Heat treatment chart for X22CrMoV12-1 Forged flat steel flat bars

FOllowing is Metallographical Test Report of 1.4923,X22CRMOV12-1 forged turbine flat bars

Welcome your inquiry of 1.4923,X22CRMOV12-1, X22CRMOV12.1,X22CrMoV121,X 12 CRMOV 12-1 forging forged steel parts